The worldwide manufacturing environment will undergo a total transformation by 2025 by following the best practices and technologies emerging from Industry 4.0. Companies now transform their industries by combining smart technology that helps automate operations while using data to make better decisions. Businesses that embrace Industry 4.0 achieve better operating performance and save money while becoming more effective. What is Industry 4.0? What goes wrong when organizations avoid this development? Firms that resist digital updates cannot maintain a market position in an accelerating technology environment.

Automotive, aerospace, healthcare, and manufacturing companies have created new technologies using AI robots and IoT technology. Your business will likely suffer if it ignores these opportunities offered by the above technologies. This blog investigates what Industry 4.0 stands for and its main components, and reveals why production facilities need them to thrive in the future.

Table of Content

What is Industry 4.0?

The Industrial Revolution 4.0 uses digital tools to change how manufacturers operate their systems. Industries use technology elements to make factories smarter by letting machines talk to each other, managing data, and making automatic choices without needing much human help.

Key Characteristics of Industry 4.0:

- Smart Factories: Real-time monitoring and self-optimization of production lines.

- Interconnectivity: The Internet of Things network devices and systems exchange information.

- Big Data & Analytics: Enhanced decision-making through AI-driven data insights.

- Autonomous Systems: Robots and AI systems now take over manual tasks.

- Cybersecurity Measures: Protecting digital infrastructure from cyber threats.

Concept of Industry 4.0

At the heart of Industry 4.0 is digitization combined with automation and smart control systems. The modern smart factory depends on AI analytics and the Internet of Things to run production better than manual and mechanical techniques. By combining Industry 4.0 technologies, manufacturers can build better outputs and deliver superior results.

Pillars of Industry 4.0

The foundations of Industry 4.0 consist of digital technology that leads manufacturing operations toward digital transformation. These technological industry 4.0 pillars support modern manufacturing progress through better operations that boost profit and market standing. Integrating smart technology with automated data systems helps businesses work better and use data to guide their decisions. Listed below are the main Industry 4.0 components showing the future manufacturing direction.

- Internet of Things (IoT)

- Artificial Intelligence & Machine Learning

- Cloud Computing & Big Data Analytics

- Cyber-Physical Systems (CPS)

- Robotics & Automation

- Cybersecurity & Data Protection

1. Internet of Things (IoT)

IoT connects digital networks between physical devices to monitor and gather real-time data. Manufacturing IoT sensors watch machines run and look at how the environment behaves to see when issues will happen early. The system helps prevent equipment breakdowns so production stays active while it saves money on repairs.

IoT lets companies check performance from their main facility across various factories simultaneously. It helps industries move to smart factories and data-based decision-making as they continue transitioning their operations to digital systems.

2. Artificial Intelligence (AI) & Machine Learning (ML)

AI and ML technologies help manufacturing systems examine data streams to enhance production performance. AI automation tools help manufacturers immediately find product issues while lowering waste to create better products.

Machine learning systems recognize equipment failure patterns from before to guide companies in planning better maintenance routines. Developing AI and ML technologies will help make production systems faster and safer while making the entire system more responsive.

3. Cloud Computing & Big Data Analytics

Cloud computing allows manufacturers to handle large datasets without the cost of building and owning their own machines. By using cloud platforms, businesses always see exact market data while making their distribution chains run better. Big data analytics gives decision-makers better results by studying large data collections to see patterns that help them recognise problems and know how to make product improvements. Organizations that use cloud technology and big data can grow their business effectively while showing customers what happens inside their operations and standing ahead of competitors.

4. Cyber-Physical Systems (CPS)

Cyber-physical systems connect digital controls with physical devices so machines respond to their environments and choose actions. These systems use actual performance data to adjust themselves automatically and increase operations’ effectiveness. Through CPS, advanced automation enables manufacturing equipment to notice and tackle problems directly while production runs. When CPS technology links computers with physical machines, it produces better production results that separate devices cannot match.

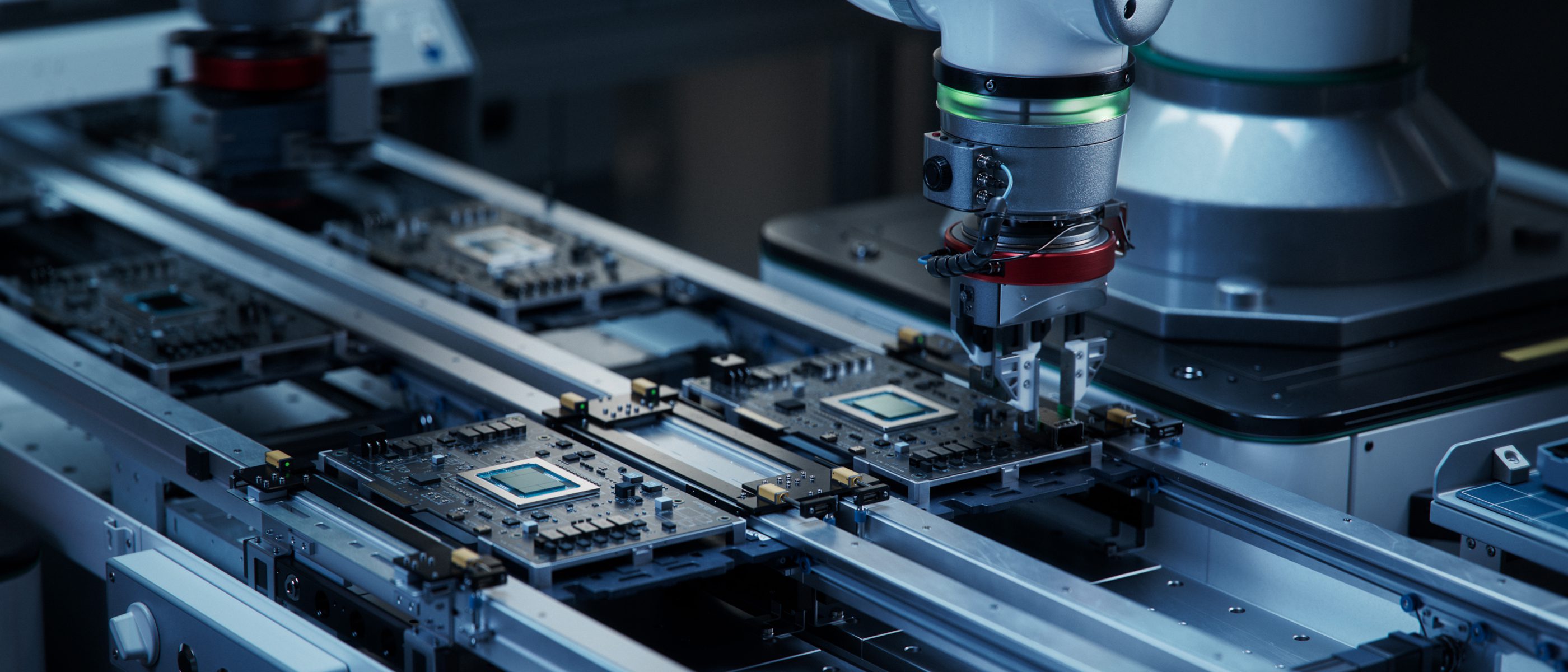

5. Robotics & Automation

Modern robotic systems now perform repetitive, heavy work tasks that humans usually do. Robots and robotic arms with AGV and cobot features increase production pace by doing work correctly and ensuring safer work areas. Robots support staff performance by producing at higher levels without losing accuracy. Improvements in robotic technologies will allow factories to become more automated systems that need less human involvement.

6. Cybersecurity & Data Protection

Manufacturing security must be strong because digital business operations depend on protecting their vital company information and customer data. Internet-connected systems in Industry 4.0 permit information exchange between networks so hackers can more easily breach these systems.

Setting up reliable security systems, encrypted data, and upholder protocols keeps business and personal information secure against unauthorized hackers. Regular system security assessments, staff training, and modern threat identification tools fortify digital security, keeping businesses secure as they function in today’s networked platforms.

Benefits of Industry 4.0

Advanced technology integration through Industry 4.0 produces major benefits in modern manufacturing. With IoT-based predictive maintenance applications, companies cut machine downtime by 50 percent while extending machine life by 20 to 40 percent. Suppliers and manufacturers stand to generate $3.7 trillion worth of new value through Industry 4.0 by 2025. The progress of modern technology helps organizations perform better while producing huge monetary development.

Industry 4.0 provides multiple benefits to business operations and manufacturing operations. Here are some benefits of Industry 4.0 that you must know:

- Automation helps production facilities work better to prevent system stoppages and resource losses.

- Smart technologies control resources better to cut business expenses.

- The tool tracks production steps to maintain high product quality without issues.

- Through AI and IoT technology, systems predict equipment failure by recognizing signs that develop before breakdowns happen.

The technology lets companies make products according to custom customer orders.

Applications of Industry 4.0 in Manufacturing

Manufacturing improves with Industry 4.0 because it uses smart technology to make products faster and better at lower costs. PwC research shows that 91% of industrial companies put money into digital factory projects, with total projected economic output surpassing $3.7 trillion by 2025. Businesses that use Industry 4.0 technologies boost their production by up to 30 percent while lowering production expenses by up to 20 percent. There are multiple ways Industry 4.0 supports manufacturing operations today.

Automotive:

Automotive manufacturers use artificial intelligence to control robots and systems that work better and deliver products more efficiently.

Aerospace:

In aerospace production, digital twins help companies test and enhance their designs without actual manufacturing costs.

Healthcare:

Using Internet of Things (IoT) technology to connect medical devices with cloud platforms and mobile apps is a big step toward creating a smart and connected healthcare system. It makes real-time data sharing, remote monitoring, and easier device use possible, all of which are key parts of what Industry 4.0 is all about. Think of smart medication dispensers that track if patients take their meds, remote tools that help doctors diagnose through telemedicine, or alerts that let you know when equipment needs attention. These are all great examples of how tech like cloud computing and data analytics can make healthcare more efficient and improve patient care.

Electronics and Consumer Goods:

Smart factories run enhanced production lines that produce more items without compromising product quality.

Industrial Equipment:

Predictive maintenance systems lower equipment breakdowns, which helps machines stay operational longer.

Industry 4.0 helps multiple fields improve their manufacturing processes through technology advancements.

Industry 4.0 Impact on Business

Industry 4.0 technologies now change how businesses work and make their products. Key impacts include:

- Staff must learn new technical skills to operate digital technology and automation.

- Businesses receive better inventory management results by using real-time data to reduce waste throughout their supply chain processes.

- Smart factories use less power to conserve the environment.

- AI tools help companies analyze business information to better forecast market changes and customer patterns.

The Future of Manufacturing with Industry 4.0

Technology advances from Industry 4.0 define how production companies must develop for success.

- New technology with artificial intelligence helps optimize production results.

- Connected IoT devices automatically send data from one machine to another, reducing operator input.

- Organizations using Industry 4.0 methods strengthen in world business markets against their competitors.

Final Thoughts

Manufacturers use Industry 4.0 to link automation systems with smart technology and data analysis to improve their operations. Organizations that adopt this new paradigm will lead the way in the changing industrial sector. MicroLOGIX works as a global industry leader to bring clients advanced Industry 4.0 technology, including automation systems and digital transformation solutions.

Our new industrial generation is now available for any business wanting to upgrade to Industry 4.0 technology. Contact us to get started

Frequently Asked Questions (FAQ)

1. What is the main goal of Industry 4.0?

Smart technology allows Industry 4.0 to improve how manufacturers operate better while managing more data and using robots.

2. How does Industry 4.0 affect job opportunities?

Automation takes over simple tasks and produces new work opportunities in AI development and technical system maintenance.

3. Can small businesses implement Industry 4.0?

Yes! Every industry level can implement Industry 4.0 features following a step-by-step schedule that matches the company’s size and spending plan.

4. What challenges do companies face when adopting Industry 4.0?

Companies that join Industry 4.0 face tough problems with their starting costs, worker education needs, and data security dangers.

5. How can businesses get started with Industry 4.0?

Begin by viewing your current production system, then add IoT systems, and use MicroLOGIX automation experts for tailored solutions.