According to Fortune Business Insights, the global Electronics Manufacturing Services (EMS) market is expected to grow from USD 648.11 billion in 2025 to USD 1 trillion by 2032, driven by increasing demand across automotive, aerospace, industrial, and healthcare sectors.

For many manufacturers, maintaining in-house manufacturing capabilities is challenging and makes no sense. It requires significant capital investment, specialised engineering resources, and constant risk management. Delays in sourcing, inconsistent quality, or lack of compliance readiness can slow innovation and disrupt product launches.

That’s why many businesses are turning to trusted OEM partners to streamline production and scale efficiently. In this article, we explore the benefits of outsourcing electronics manufacturing in 2025, including faster time-to-market and the flexibility to meet changing demands, all the while maintaining product quality and regulatory compliance.

Table of Content

1. Faster Time-to-Market

Speed is crucial when launching new products to respond rapidly to meet market demands. Working with a capable EMS partner streamlines production timelines—from design hand-off to final assembly.

Time-saving capabilities:

- Quick-turn prototyping services with end-to-end assembly

- New Product Introduction (NPI) process to fast-track production readiness

- Design for Manufacturability (DFM) review to reduce iterations

- Integrated component sourcing, kitting, and importing to avoid supply chain delays

- Board bring-up, functional testing, and ready-to-dispatch packaging—all under one roof

These services reduce lead times and speed up your go-to-market journey. If you’re exploring dependable PCB Assembly Services that support faster, smoother product launches, MicroLOGIX offers all the above services designed to help OEM customers.

2. Cost-Efficient, Scalable Production

Building and managing internal manufacturing capacity is resource-intensive. Outsourcing allows predictable costs, flexible scaling, and access to supply chain leverage, especially for OEMs with fluctuating demand.

Cost and scale benefits include:

- Mass manufacturing capabilities for consistent high-volume output

- Prototyping-to-production transition with minimal reengineering

- Kitting of components and inventory handling are managed efficiently

- Support for batch labelling (QR codes, serials, traceability) for industrial scale

- Streamlined testing and ESD-compliant packing

This model helps you scale production while optimizing operational spend.

3. High Product Quality and Reliability

Quality assurance is non-negotiable, especially in sectors like aerospace, automotive, and healthcare. Outsourcing to a certified EMS partner ensures process reliability, industry compliance, and product integrity.

Quality-focused practices include:

- Certifications: AS9100, ISO 9001, IATF16949, ISO 14001

- Full suite of functional, burn-in, vibration, and temperature cycling tests

- Automated Optical Inspection (AOI) and X-ray inspection at key checkpoints

- In-line support for UL, CE, and MIL-461F compliance

- Conformal coating, final assembly, and Final Acceptance Tests

With these measures in place, quality is designed into every stage of production. To maintain that level of quality, you need expert engineering guidance throughout the product life cycle.

4. Technical Expertise and Engineering Support

An experienced EMS partner brings deep technical knowledge – essential when designing for manufacturability, sourcing hard-to-find components, or testing complex board functionalities.

Engineering support you can rely on:

- Collaborative DFM and Dfx (Design for Excellence) feedback

- Early-stage FMEA analysis for thermal and structural risks

- Component sourcing and importing through reliable vendor networks

- Higher-level assembly, box build, and system integration expertise

- Ongoing support from production engineering teams for smooth scaling

This technical partnership helps engineering and R&D teams stay focused on innovation, not logistics. If you require early-stage builds or design validation, MicroLOGIX Provides Quick-turn Prototyping Services to help accelerate development cycles with minimal friction.

5. Reduced Supply Chain and Compliance Risk

Outsourcing reduces the operational burden of managing multi-vendor supply chains and evolving regulatory demands, especially in safety-critical industries.

Risk-reduction strategies include:

- In-house pre-compliance testing for CE/UL

- Access to MIL-461F testing for defense and avionics-grade products

- Traceable batch coding, barcode & QR labelling for audit and warranty workflows

- Strict ESD-safe material handling and packing

- End-to-end management of component kitting, sourcing, and packaging

These services allow OEMs to mitigate risk while maintaining transparency and accountability.

6. Custom Solutions for Complex Sectors

Not all industries have the same performance requirements. Whether you’re designing rugged systems for defense or miniaturised electronics for healthcare, outsourcing offers flexibility and sector-specific understanding.

Examples of tailored services:

- Temperature cycling and vibration testing for aerospace and defense

- Wire harness and enclosure fabrication for industrial applications

- Clean, traceable PCBA assembly for medical-grade electronics

- System integration and burn-in testing for high-reliability automotive systems

Each build is adapted to meet the performance, compliance, and lifecycle needs of your sector.

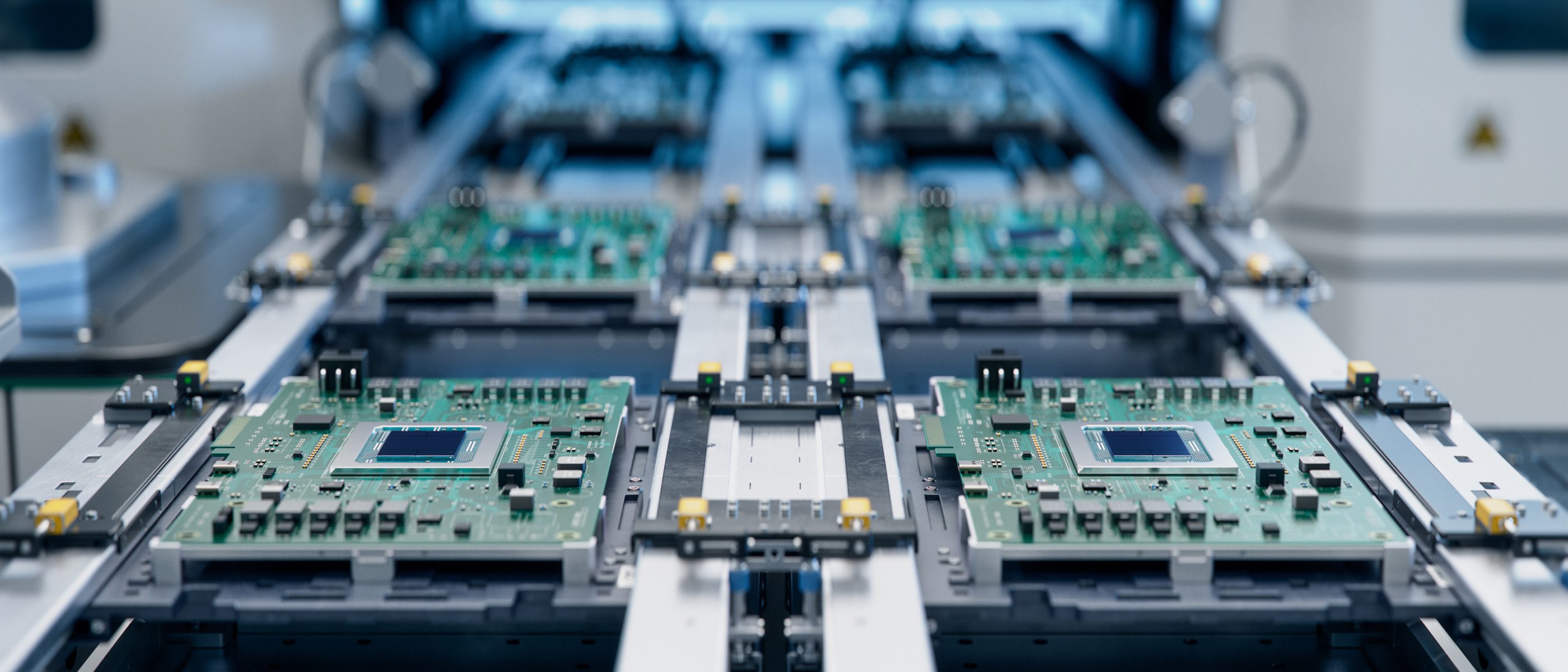

7. Access to Advanced Manufacturing Infrastructure

Outsourcing removes the burden of investing in expensive, high-maintenance production equipment. Instead, you gain immediate access to a high-end infrastructure capable of supporting both complex low-volume prototypes to high-volume runs.

What this includes:

- High-speed, modern SMT pick and place machines for precise component assembly

- 12-zone RoHS-compliant reflow ovens ensuring solder reliability through thermal stability

- Automatic Optical Inspection (AOI) and X-ray inspection for thorough quality control

- Burn-in ovens and BGA rework stations for advanced test and repair capability

- Full support for fine-pitch components (0201, μBGA, CSBGA)

This infrastructure supports fast, accurate, and high-yield PCB assemblies without the overhead of in-house setup.

Why MicroLOGIX Is a Trusted OEM Partner?

MicroLOGIX combines deep industry experience with certified processes and end-to-end capabilities, making it a dependable choice for OEMs seeking precision, reliability, and scale.

What sets us apart:

- 25+ years of experience serving defense, aerospace, automotive, industrial, and healthcare sectors

- Certified to AS9100, IATF16949, ISO 9001, and ISO 14001

- Full in-house services: prototyping, PCB assembly, box build, testing, and final integration

- Support for CE, UL, and MIL-461F compliance

- Advanced infrastructure, including SMT lines, AOI, X-ray, and burn-in testing

- Traceability built in: batch coding, QR/serial labels, ESD-safe packing

With MicroLOGIX, the Best Electronic Design and Manufacturers in Bangalore, manufacturing becomes a seamless extension of your product strategy, built on quality, speed, and technical confidence.

FAQ’s

- Is outsourcing cheaper than making everything in-house?

Yes, building your own setup takes a lot of money, time, and people. By outsourcing, you only pay for what you need, whether it’s a small or large batch. So it’s easier to manage costs and scale up.

- Will the quality of my product be good if I outsource?

Definitely. EMS partners follow strict quality checks and international standards. They do regular inspections, testing, and certifications to make sure everything works perfectly, especially important if you’re in industries like healthcare or aerospace.

- What if I’m in a special industry like medical or defense? Can they handle that?

Yes, OEM manufacturers know the rules and standards for different industries. Whether it’s medical, defense, or automotive, they use the right materials, tests, and processes to meet your industry’s needs.