Remote Monitor and TRACKER

Remote Off-Road Vehicle Monitoring

Off-road vehicles and mobile industrial equipment operate in remote, demanding environments where visibility is limited and failures are costly. When equipment is deployed across construction sites, mines, or industrial projects, even a small issue can escalate into unplanned downtime, delayed operations, and higher service costs.

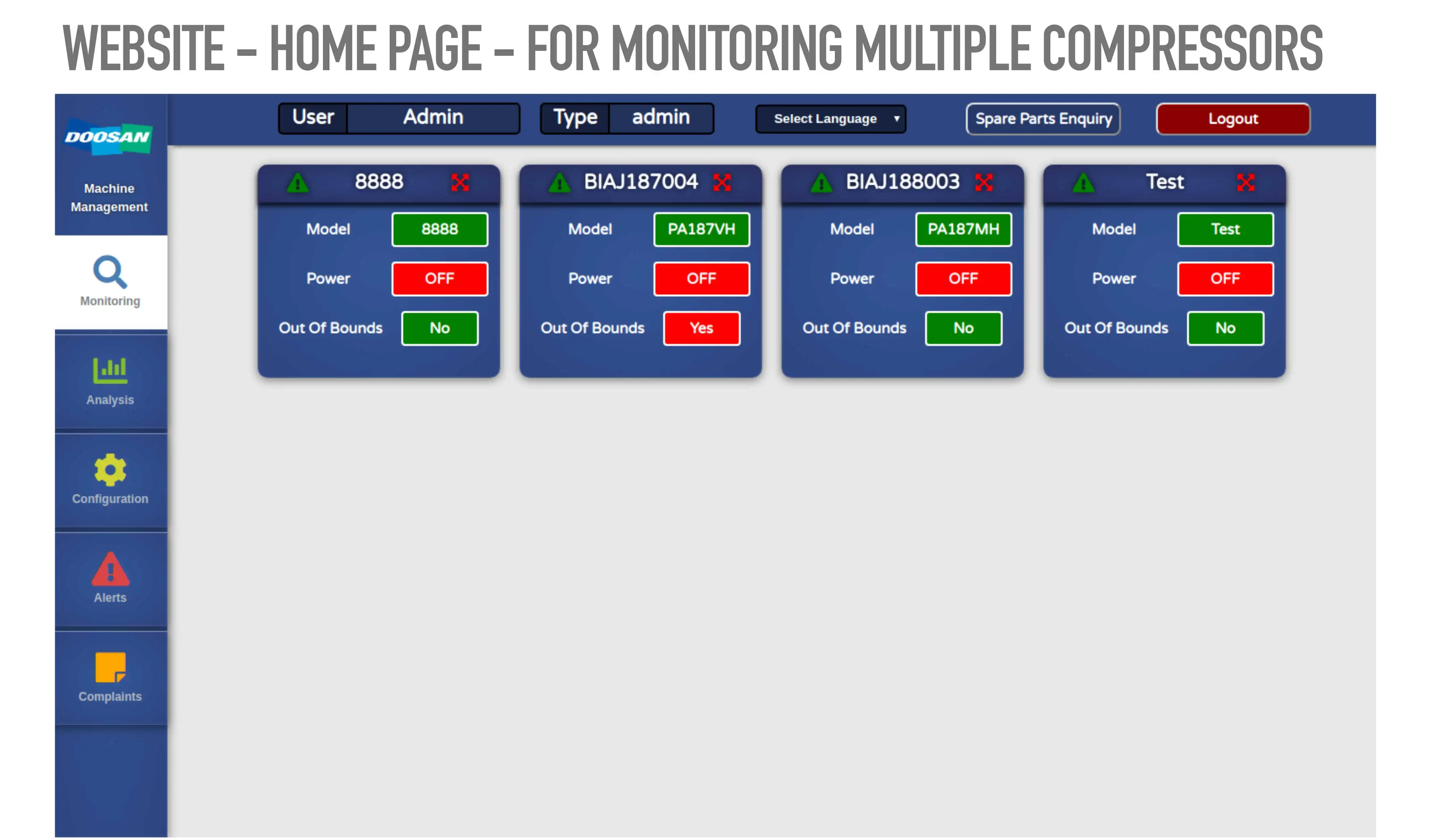

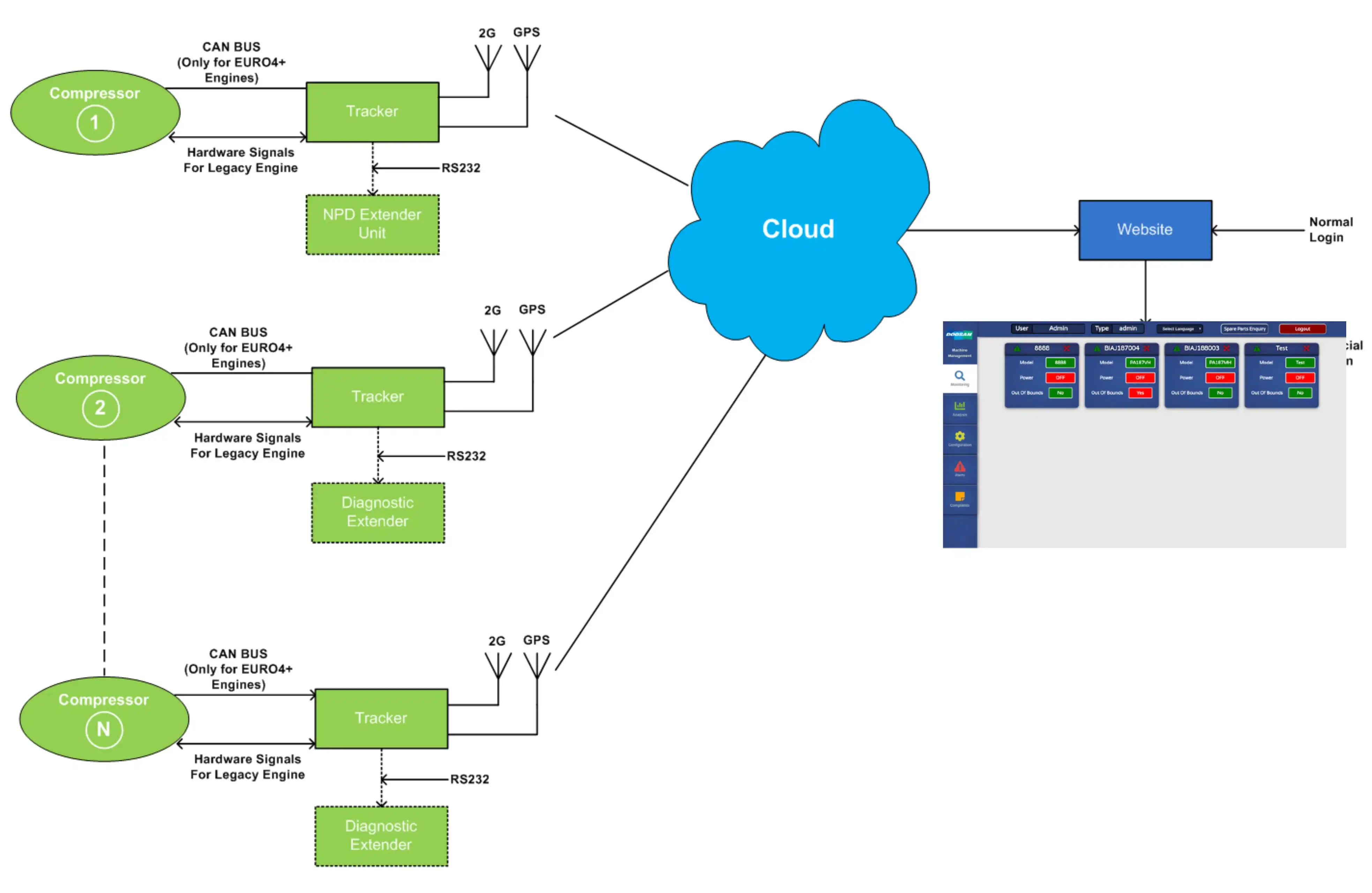

Multiple Compressors Monitoring - Overall System

Product Overview

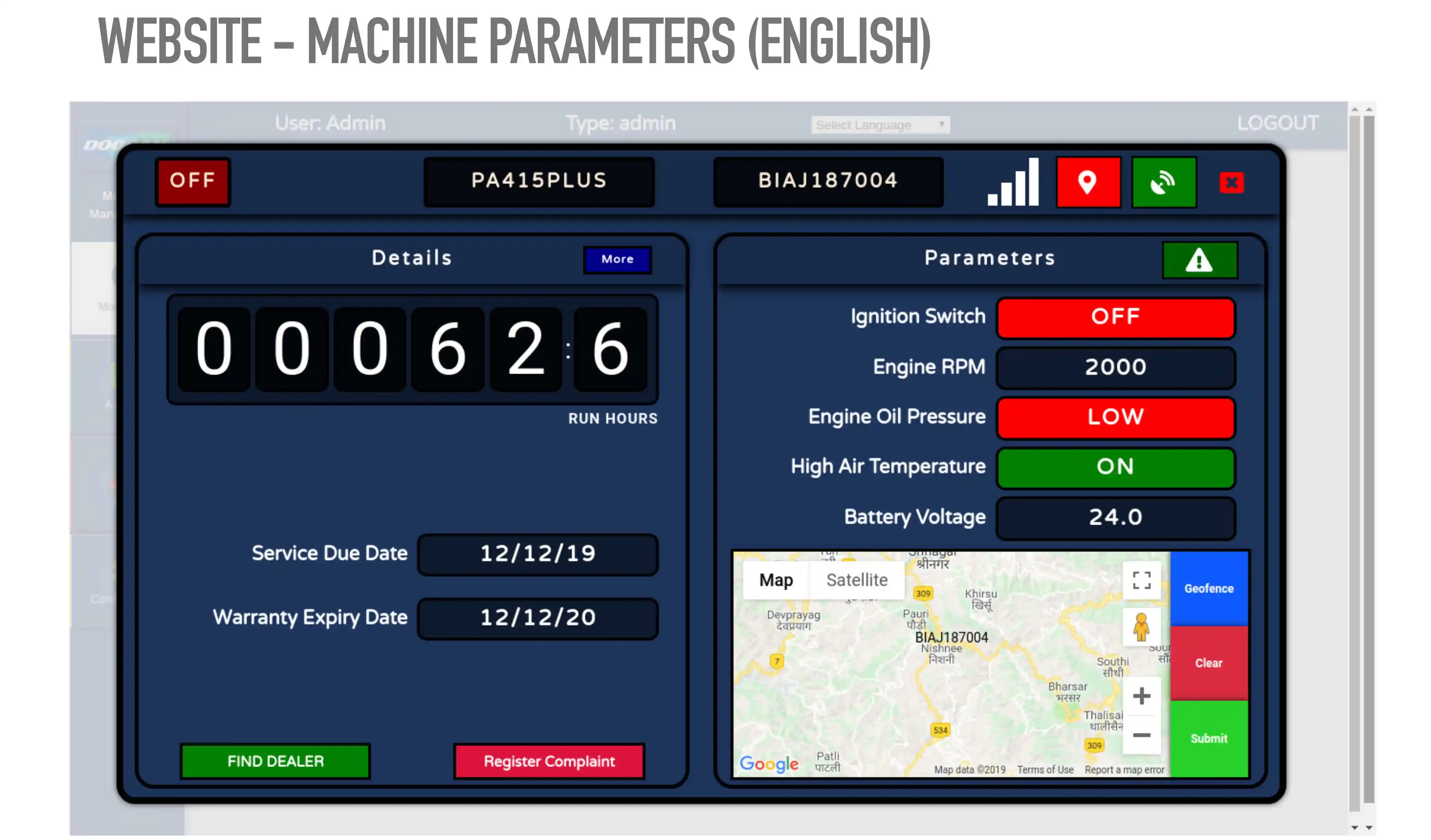

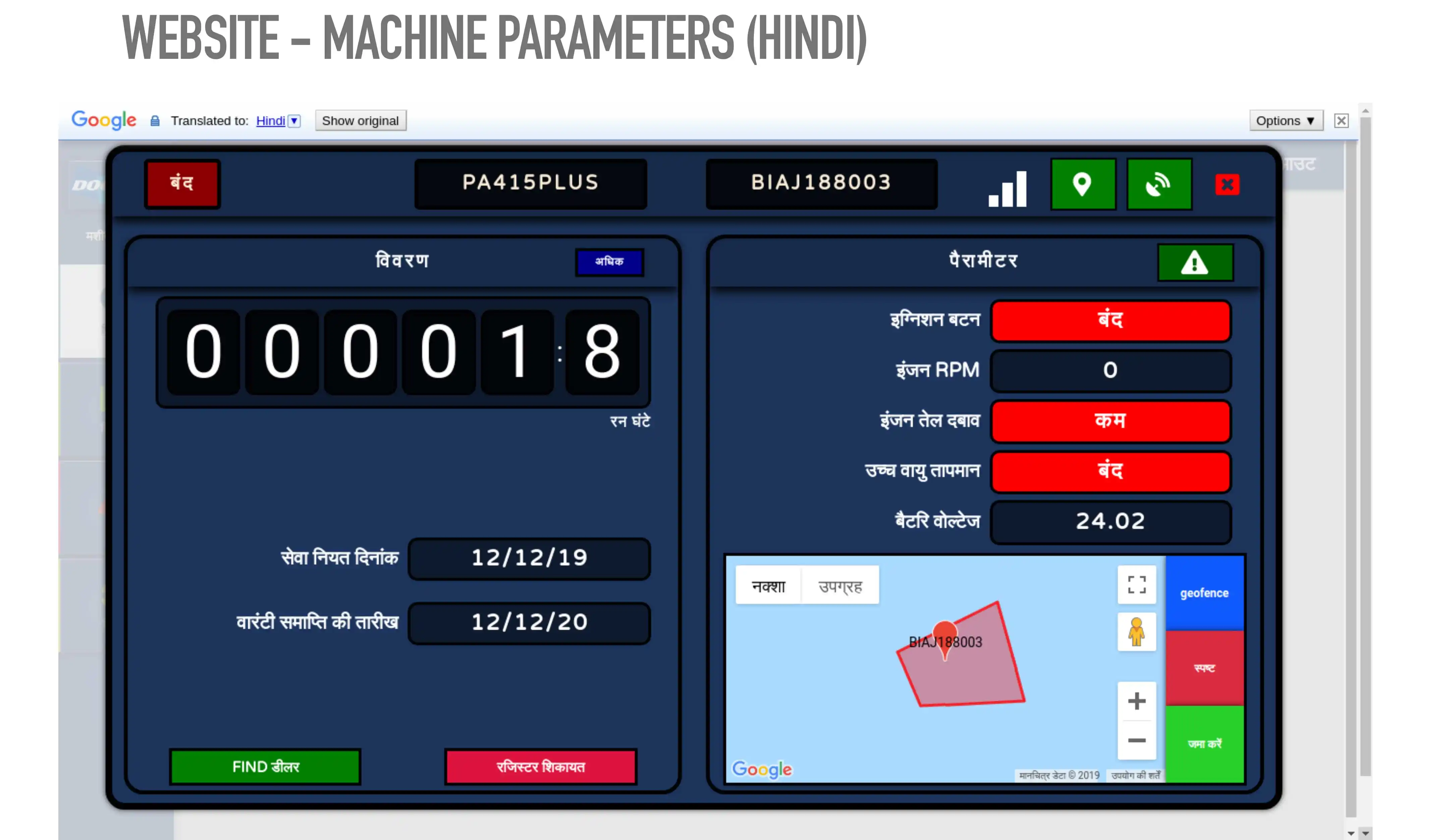

Core Monitoring Capabilities

Real-Time Vehicle and Engine Health

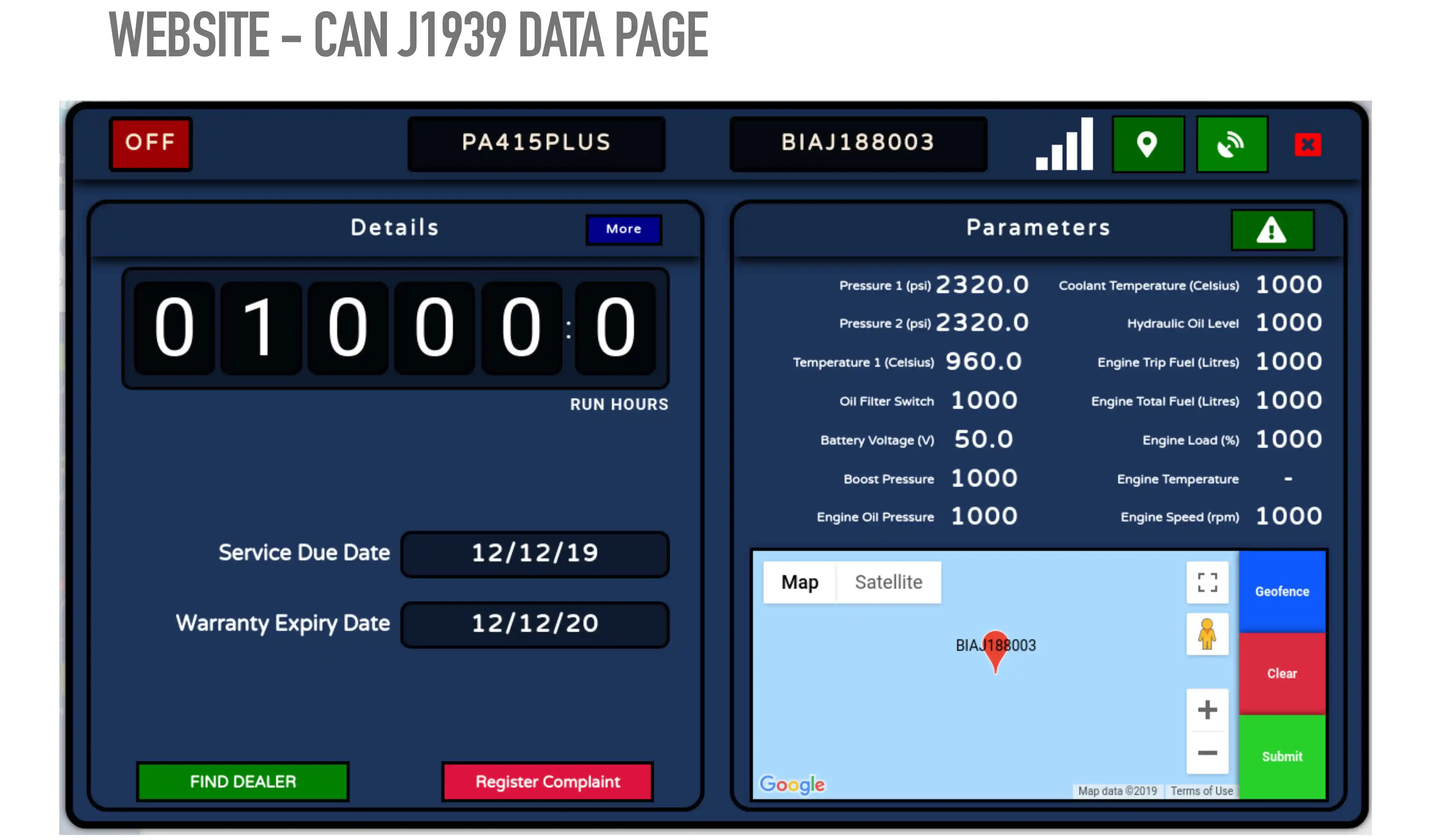

The system continuously monitors critical engine and operating parameters such as RPM, oil pressure, coolant temperature, battery voltage, fuel usage, engine load, discharge temperatures, and hydraulic oil levels. By tracking these values with accurate timestamps, operators gain early visibility into abnormal behavior. This allows maintenance teams to intervene before minor deviations turn into breakdowns or costly site visits, improving overall equipment reliability.

Advanced Diagnostics via CAN J1939

GPS Tracking and Geo-Fencing

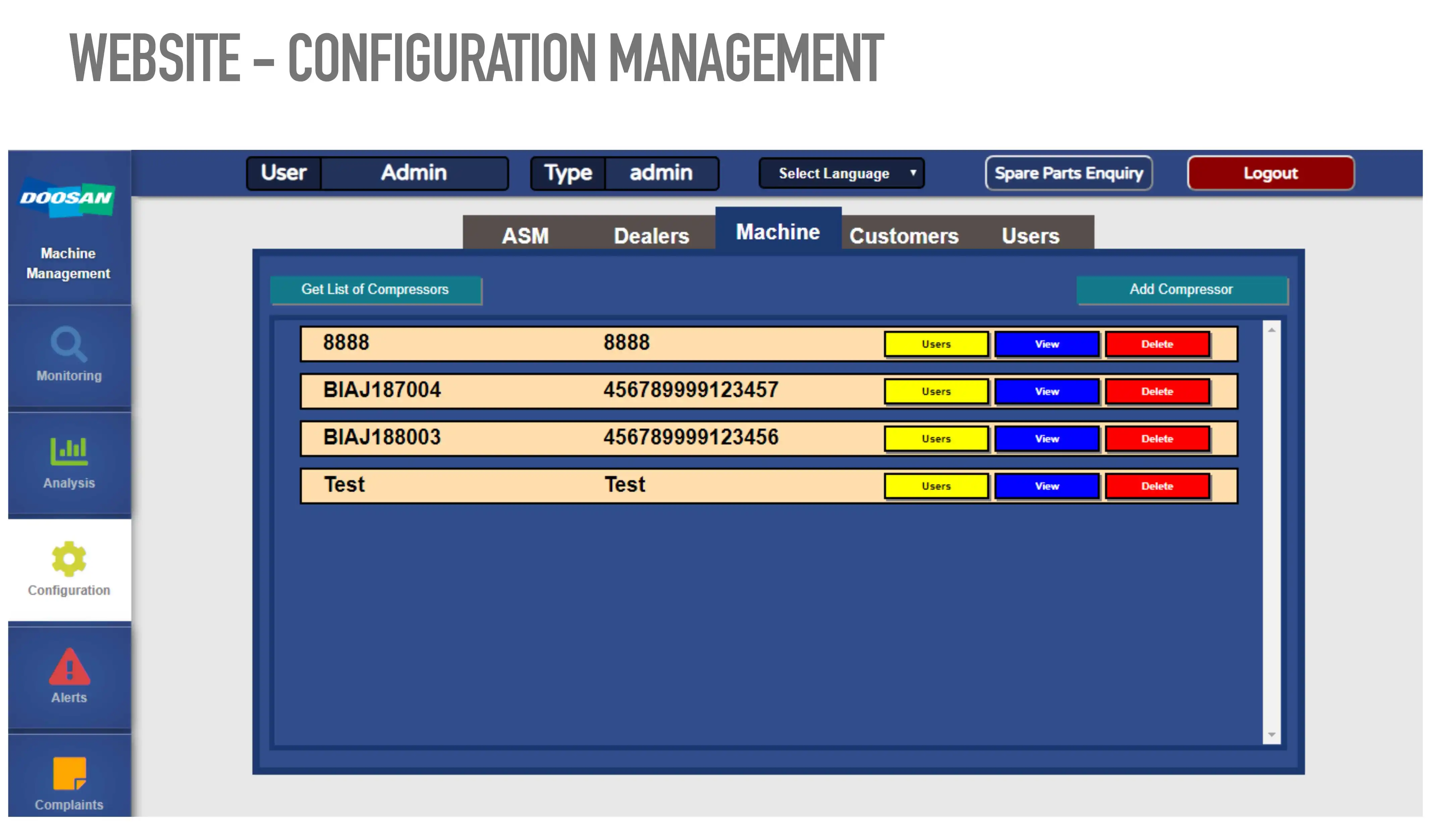

Cloud Dashboard and User Access

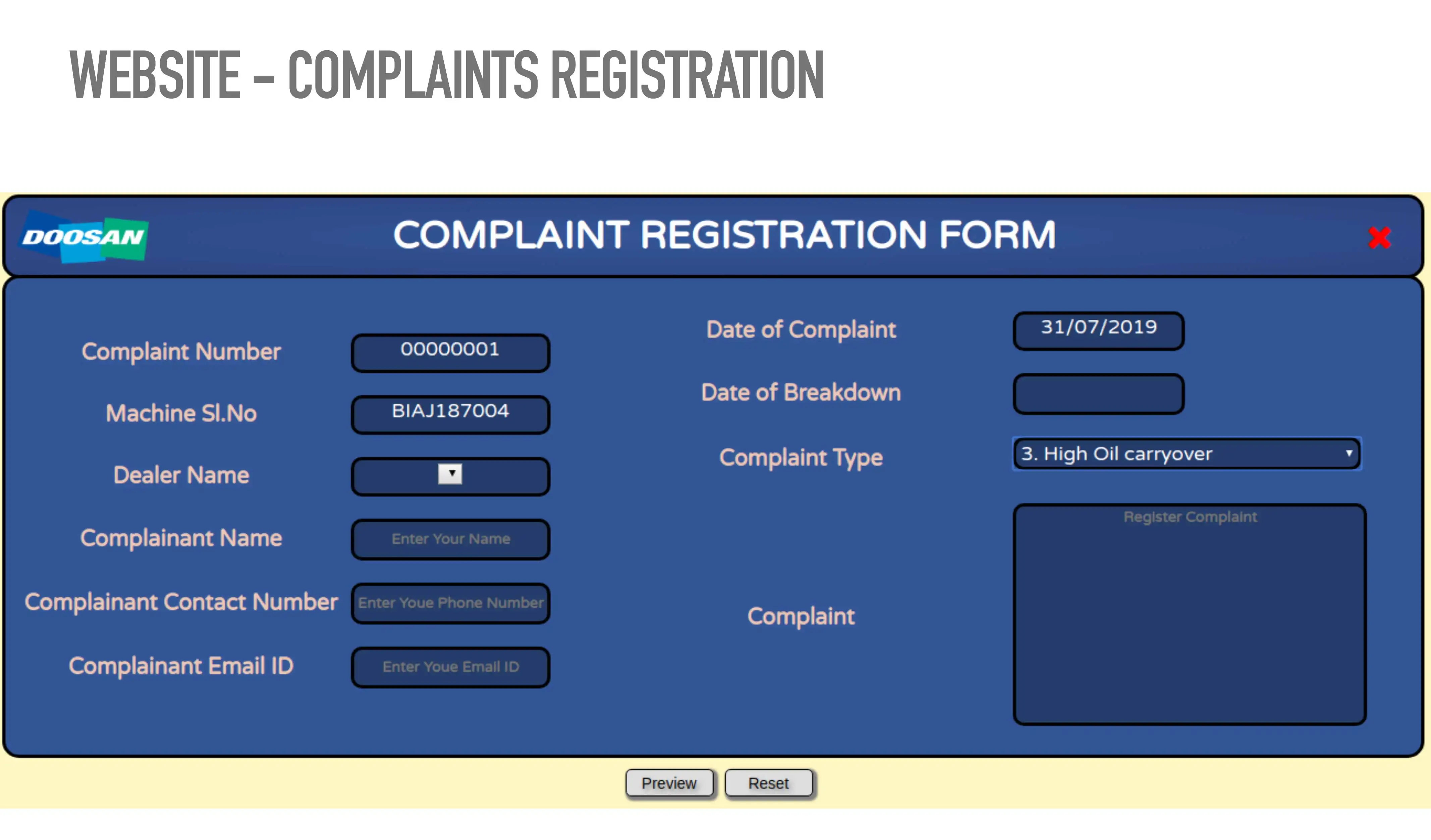

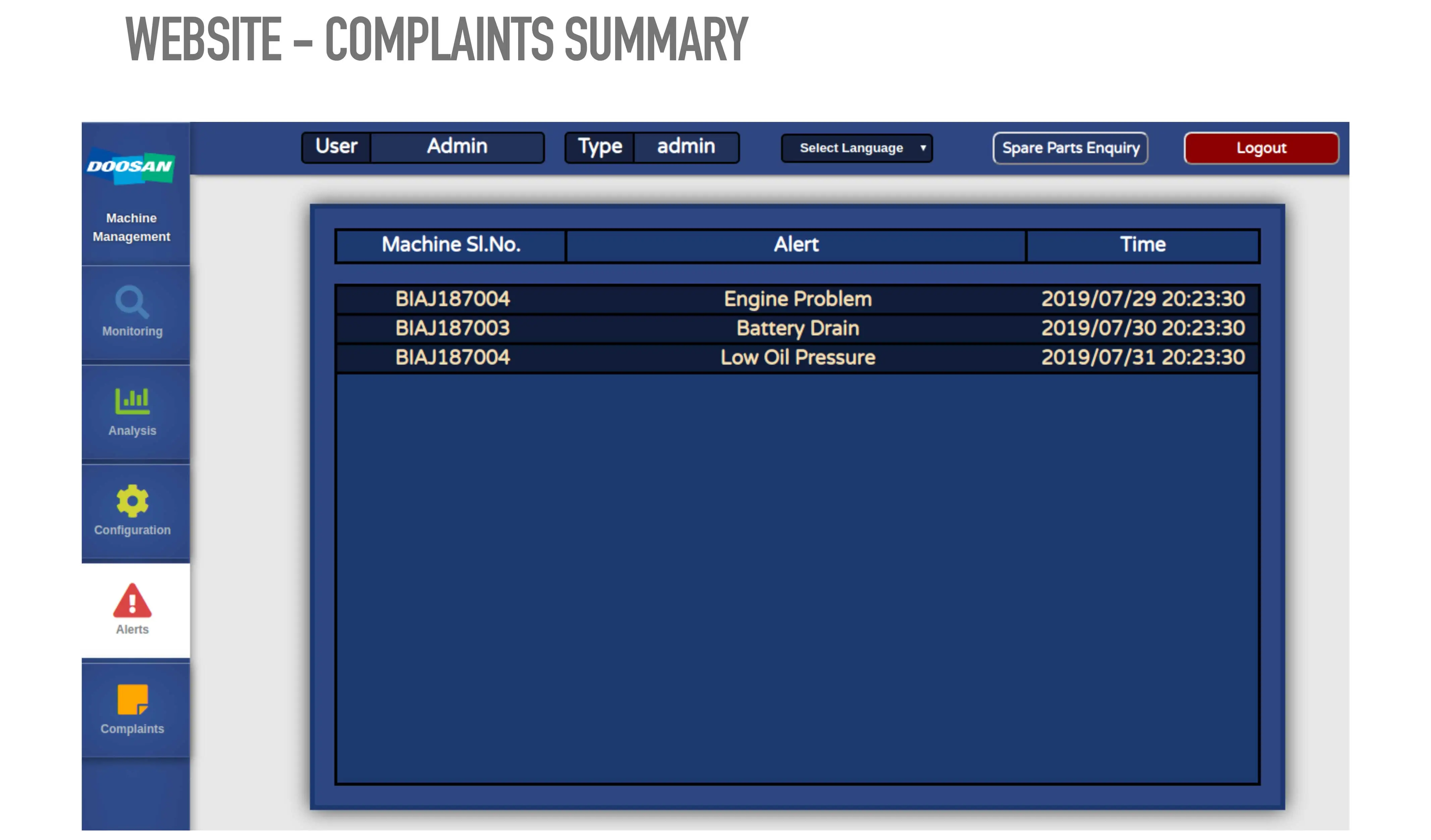

Service and Complaint Management

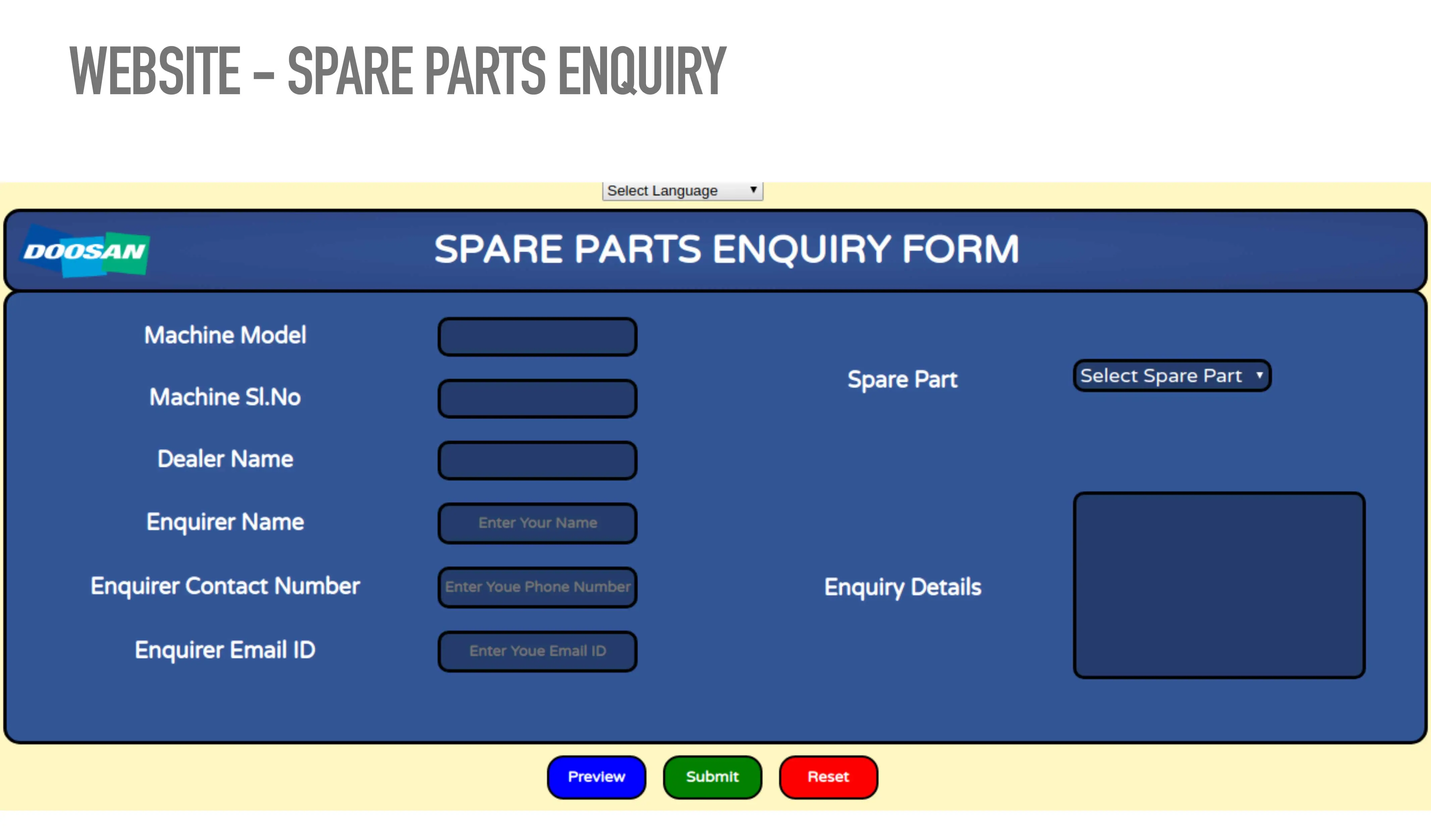

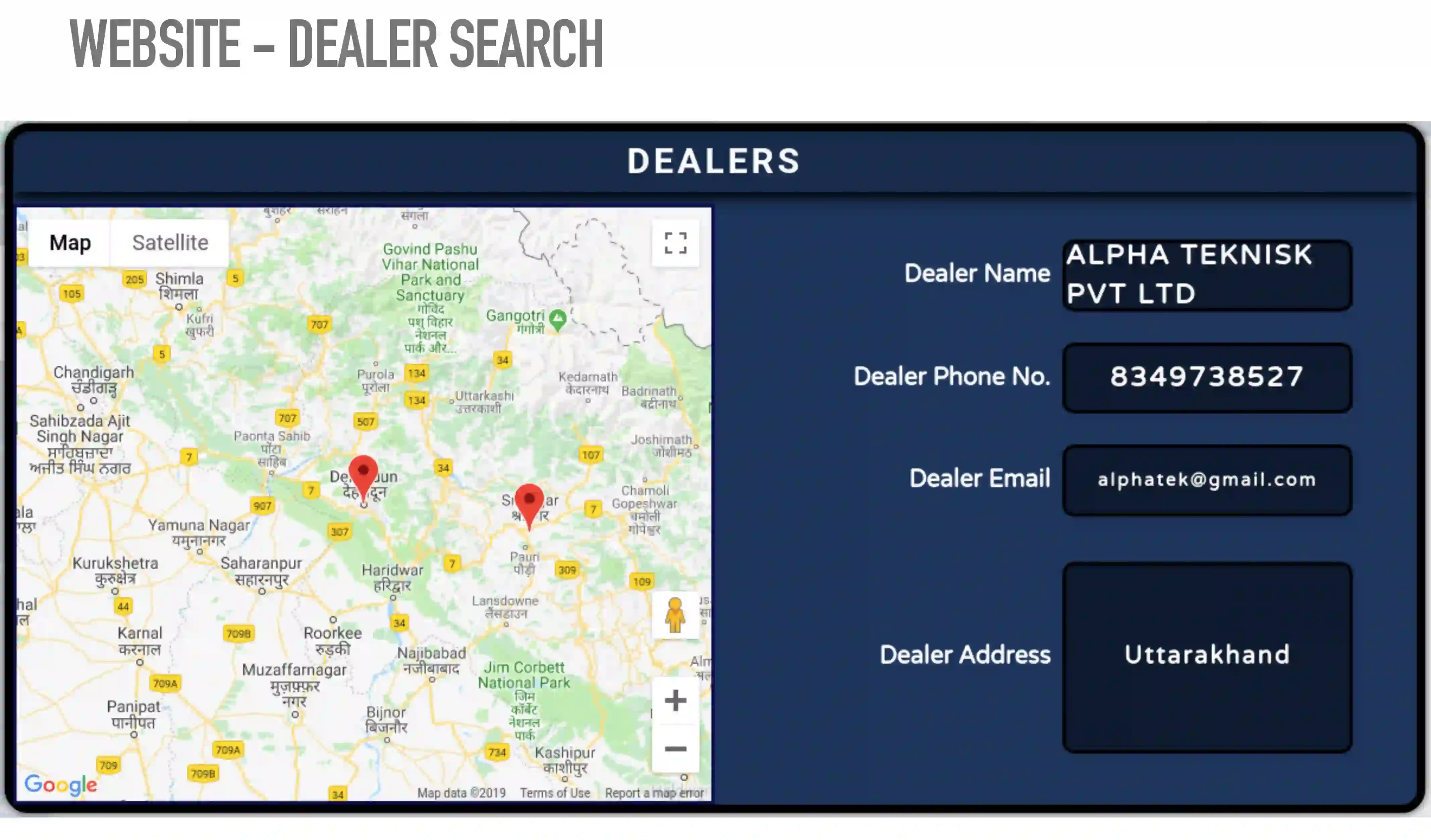

Dealer Search and Spare Parts Enquiry

Use Cases

Rental Fleets

Accurate run-hour calculation ensures transparent billing and helps identify early signs of misuse. Continuous monitoring reduces sudden breakdowns and simplifies planning for scheduled maintenance across distributed rental assets.

Mining and Heavy Construction

In challenging environments with high thermal and load stress, the system helps detect overheating, pressure deviations, and unusual operating patterns. This minimizes unplanned site visits, reduces downtime, and supports preventive maintenance in remote locations.

Mining and Heavy Construction

Generators and Mobile Industrial Equipment

OEM Warranty and Service Teams

Technical Specifications

- Integrated 4G/LTE modem with GPS receiver, with 2G fallback support

- CAN J1939 support for electronic engines

- RS232 and sensor-based inputs for mechanical engines

- Real-time data logging with offline storage during low or no signal

- Cloud-based dashboard with multilingual support

- Alerts via SMS, email, and web interface

- Water-resistant, dust-proof ABS enclosure

- Google Maps integration for location visualization