Table of Contents

The Future of Electronics Manufacturing Is No Longer in the Cloud – It’s at the Edge

Until a few years ago, most Electronics Manufacturing Services (EMS) providers saw AI as something that lived in massive data centers – crunching numbers far away from the factory floor. But that’s changing fast.

By 2026, embedded AI integrated into machines, sensors, and control systems is expected to influence how EMS operations approach decision-making, anomaly detection, and real-time efficiency.

Consider it this way: instead of uploading raw production data to the cloud for processing, edge-based embedded AI allows machines to think for themselves. In future-ready EMS environments, a pick-and-place machine could recognize a solder defect instantly, while a conveyor system could adjust its pace to prevent bottlenecks, and a PCB line could forecast a component shortage ahead of time.

This shift marks the beginning of the Edge Revolution across the global EMS industry.

What Is Embedded AI?

Embedded AI is defined as artificial intelligence software programs that are implemented in hardware devices like microcontrollers, sensors, and industrial machines. The AI systems execute locally at the data source without a constant connection to a cloud server.

Here’s the difference in simple terms:

- Cloud AI: Data travels from the factory to a remote server, gets processed, and then returns insights.

- Embedded (Edge) AI: Data is analyzed directly on-site, in milliseconds, allowing immediate action.

The result? Faster decisions, reduced latency, higher security, and more autonomy.

This is especially important in electronics production, where milliseconds count. Whether checking PCBs, calibrating equipment, or coordinating component feeds, embedded AI keeps things running smoothly, uniformly, and quickly.

Edge vs. Cloud AI: Why It Matters in Manufacturing

Cloud AI has scale and computing power, but it’s slow for time-critical manufacturing tasks. For example, imagine an SMT (Surface Mount Technology) line detecting a soldering issue. With cloud AI, by the time data travels and returns, hundreds of boards might already have defects.

Edge AI eliminates that delay.

It enables real-time data processing right where it’s needed. This distinction is crucial for EMS automation. Here’s a comparison:

| Parameter | Cloud AI | Embedded / Edge AI |

| Latency | Seconds | Milliseconds |

| Data Security | Data travels via the internet | Data stays on-site |

| Connectivity | Needs reliable internet | Works even offline |

| Use Case Fit | Analytics and planning | Real-time control and automation |

In short, edge computing in manufacturing empowers machines to think, adapt, and optimize instantly-no external dependencies.

The Rise of Embedded AI in EMS

EMS companies have always thrived on precision and speed. But as product complexity grows, IoT boards, miniaturized sensors, high-speed connectors, manual or even semi-automated QA processes can’t keep up.

Embedded AI is closing that gap.

Across India’s evolving EMS environment, early-stage adoption of embedded AI is beginning to appear in areas such as inspection systems and automation equipment. These systems are designed to detect subtle misalignments, identify thermal anomalies, and support predictive maintenance models.

Industry studies indicate growing interest and pilot-level adoption of edge-AI systems among EMS providers worldwide, according to a 2025 survey by Deloitte, with India becoming one of the main adoption centers due to its accelerated Industry 4.0 transformation and export of electronics.

5 Key Areas Where Embedded AI Is Transforming EMS

1. Real-Time Data Processing

Traditional systems collect and forward data to central servers. Embedded AI processes it instantly.

- Detects line stoppages within milliseconds.

- Enables adaptive machine tuning on the fly.

- Reduces downtime by up to 25% (based on industry averages).

2. Predictive Maintenance in Manufacturing

Instead of reactive maintenance (fixing after failure), embedded AI continuously monitors vibration, temperature, and load data to predict failures before they occur.

- AI models detect micro-patterns invisible to human operators.

- Maintenance schedules become proactive, not calendar-based.

- Result: longer machine life and fewer production disruptions.

3. Automated Quality Inspection

Advanced EMS facilities worldwide are beginning to introduce AI-assisted AOI, SPI, and X-Ray inspection systems.

- These systems identify solder joint issues, misplacements, or cracks in milliseconds.

- These systems are designed to improve defect recognition accuracy as inspection datasets grow.

- The result is near-zero false rejects and consistent quality across high-volume runs.

4. Energy Efficiency and Sustainability

Embedded AI is being explored as a way to optimize energy consumption through intelligent control of HVAC, lighting, and machine power loads.

- Edge algorithms analyze peak usage patterns and cut idle energy drain.

- This not only lowers operational costs but also supports green manufacturing initiatives.

5. Human-Robot Collaboration (Cobots)

Edge-based intelligence is enabling the next generation of collaborative robots designed to work safely alongside humans.

- Embedded AI enables instant object recognition and motion prediction.

- Cobots can handle complex assembly without risking safety or speed.

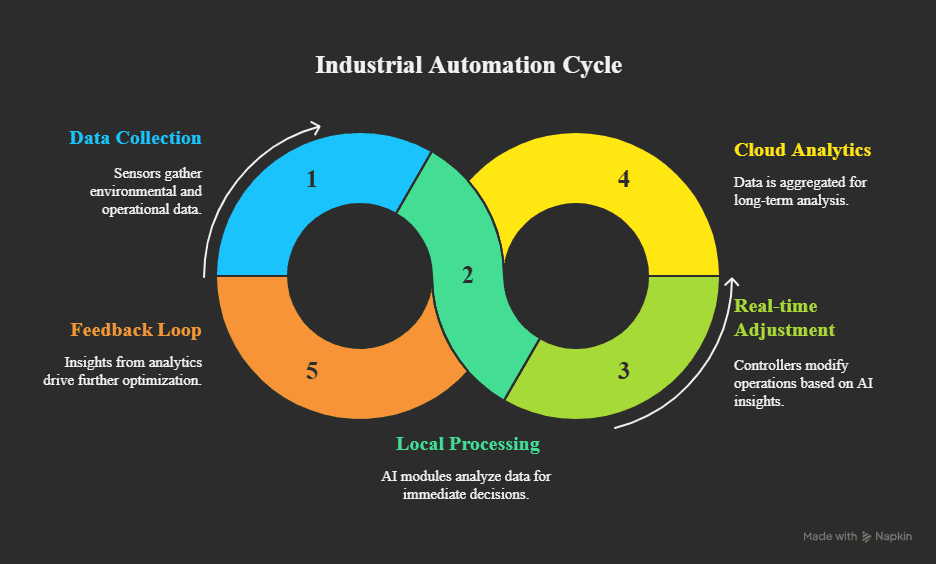

Smart EMS Workflow with Embedded AI at the Edge

Here’s a quick visual breakdown of how embedded AI powers the modern EMS ecosystem. The diagram below shows how intelligence flows between machines, sensors, controllers, and the cloud inside a modern EMS setup.

AI and IoT Integration: The Perfect Duo for Industry 4.0 in Electronics

AI alone can analyze. The IoT alone can connect. But together, they transform manufacturing ecosystems.

When AI and IoT integration happen at the embedded level, the factory becomes a living network where every device senses, interprets, and acts.

In advanced EMS environments, AI-enabled IoT nodes can track parameters such as cleanroom humidity and solder paste viscosity. These networked systems contribute to an integrated digital twin, an online model that captures the shop floor’s current state.

This intersection of AI, IoT, and edge computing defines the direction of Industry 4.0 in electronics manufacturing: smart, data-based, and responsive production.

The Road to 2026: What’s Next for EMS Companies

By 2026, embedded AI will be as standard in EMS as PLCs or vision systems are today. But successful adoption will depend on three strategic factors:

- Hardware-AI Alignment: Choose controllers and microprocessors that support AI inference locally.

- Data Readiness: Standardize data formats across production and testing systems for smooth AI deployment.

- People + AI Collaboration: Train engineers not just to use AI but to understand it, bridging the gap between manufacturing expertise and data science.

The next phase will move from AI-assisted lines to AI-orchestrated factories, where entire production ecosystems self-optimize.

For forward-looking EMS providers, understanding this evolution is becoming increasingly important.

Conclusion: From Automation to Intelligence

Embedded AI is not replacing human intelligence; it’s amplifying it.

By bringing computation closer to the action, EMS companies can act faster, waste less, and deliver higher reliability, all while staying secure and data-sovereign.

Here’s the bottom line: The EMS industry’s edge revolution has begun. The smartest factories of 2026 won’t just make electronics, they’ll think in real time.