Your Vision, Our Technology

Machine Monitoring Solutions with Cloud Dashboard

Industrial machines operate in demanding environments where undetected issues can lead to downtime, service delays, and higher operating costs. Without continuous visibility, machine owners and operations teams often rely on manual inspections or delayed reports that fail to capture early warning signs.

MicroLOGIX Machine Monitoring Solutions provide continuous visibility into machine health, usage, location, and operating conditions through a centralized, cloud-based dashboard. The solution is designed for industrial operators, OEMs, and service teams that need reliable operational data to support maintenance planning, reduce downtime, and manage distributed equipment more effectively.

Product Overview

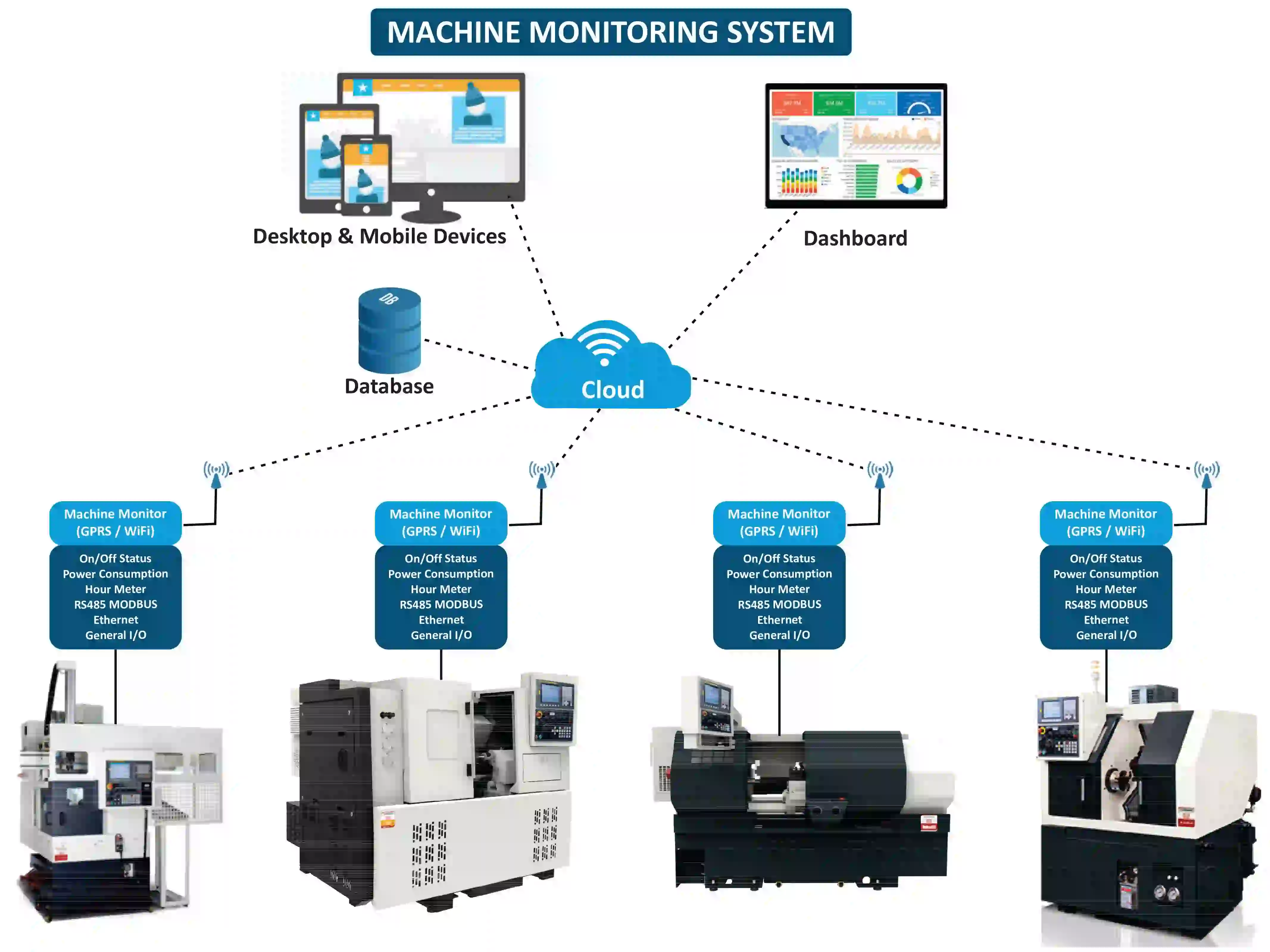

The solution combines an industrial-grade machine monitoring controller with cloud connectivity and a centralized web portal. It supports a wide range of industrial and mobile machines and enables continuous data acquisition from critical operating parameters.

Machine data is transmitted to the cloud for visualization, alerts, and historical analysis. When network connectivity is unavailable, the system continues to log data locally and automatically synchronizes once communication is restored. This ensures complete machine history and consistent reporting across remote or mobile deployments.

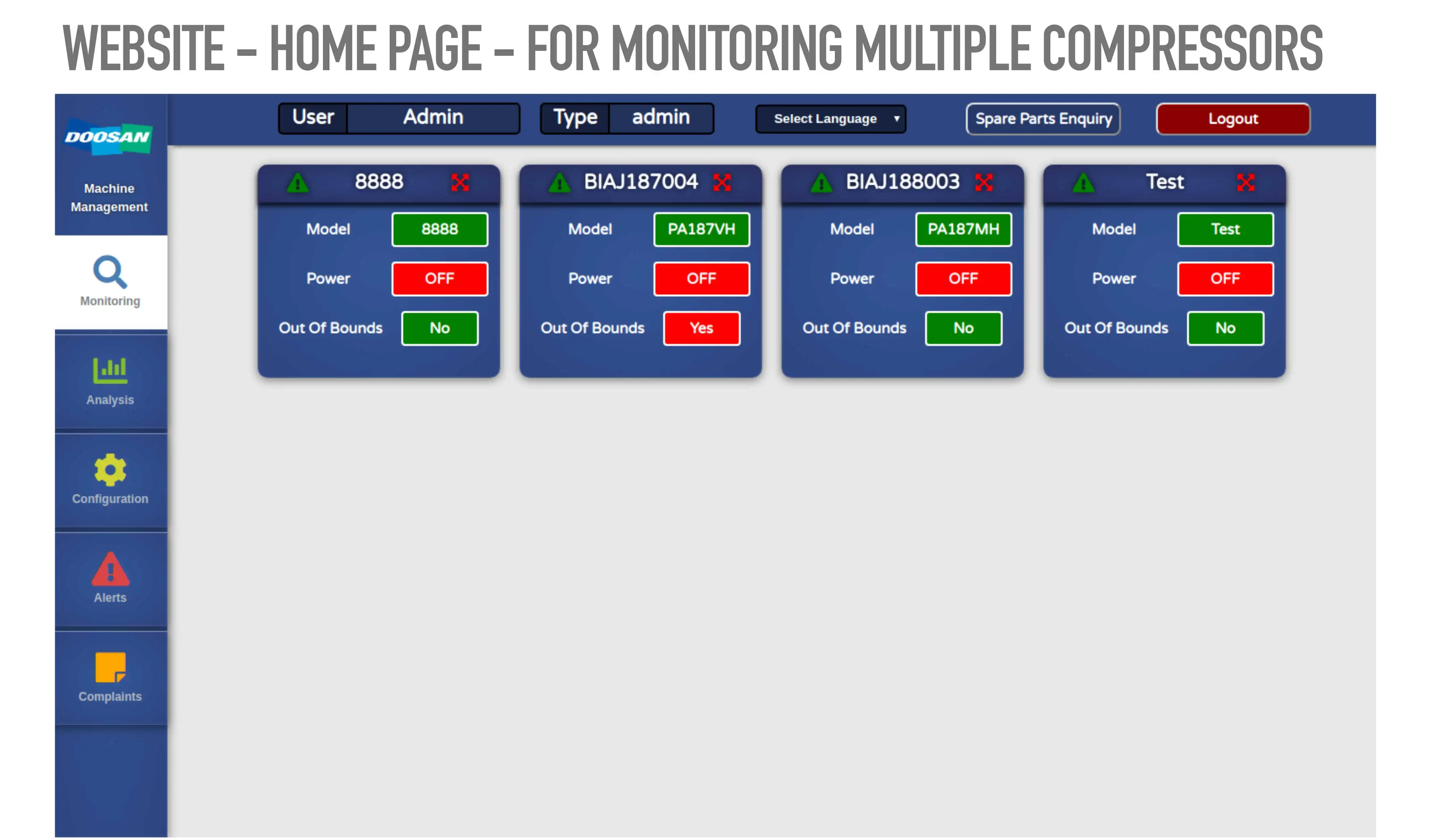

The platform is designed to support monitoring of single machines as well as large machine fleets without adding operational complexity.

MACHINE MONITORING SYSTEM

MULTIPLE MACHINES MONITORING - OVERALL SCHEME

Core Capabilities

Machine Health and Usage Monitoring

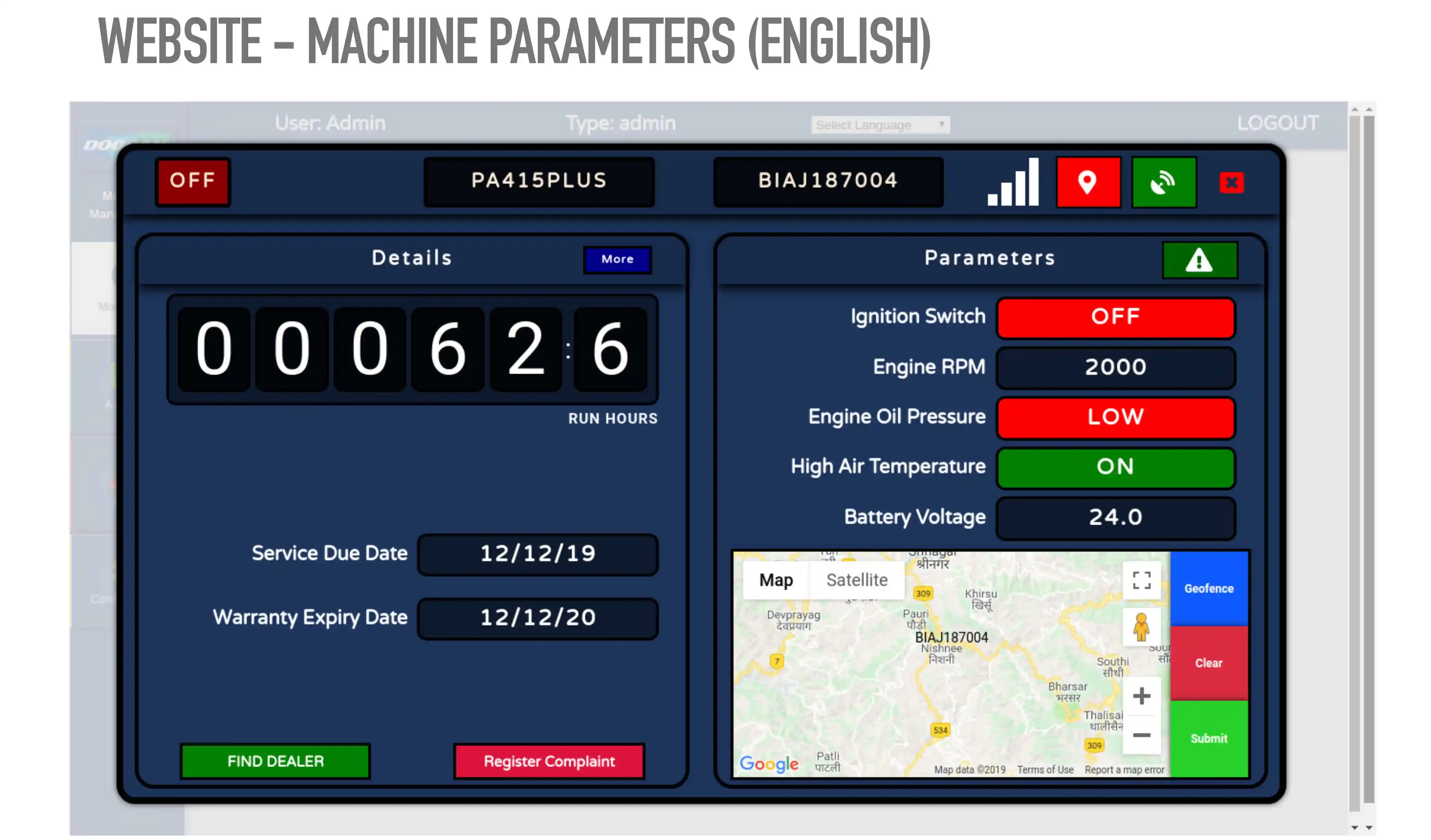

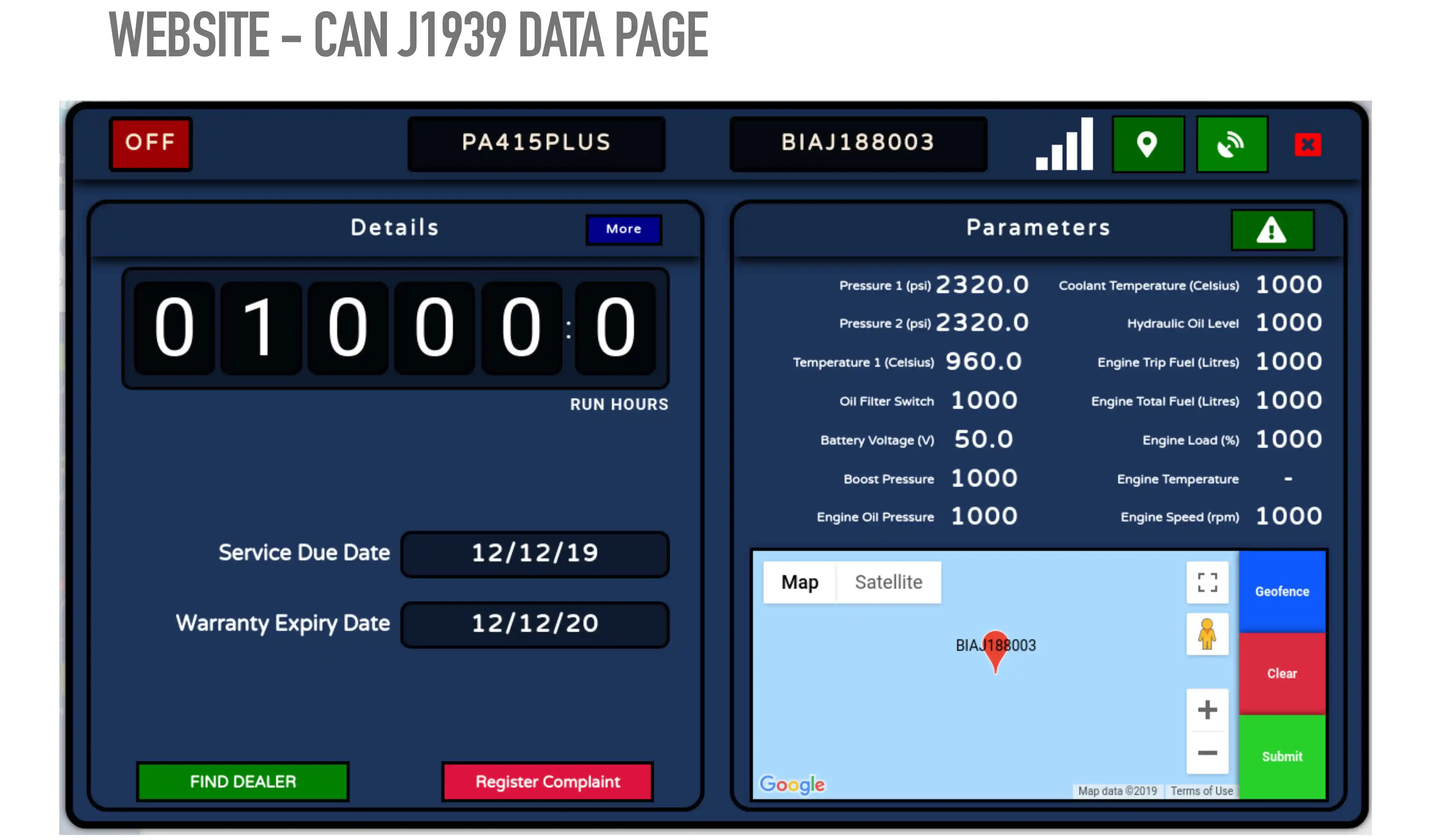

The system continuously tracks machine operating status, run hours, and key performance parameters. Run-hour calculation is based on validated logic using ignition status and machine RPM rather than simple timers. This provides dependable data for maintenance planning, service scheduling, and warranty tracking. Operators can clearly see which machines are running, idle, or operating outside normal conditions.

Condition-Based Maintenance Support

By recording and analyzing operational trends over time, the system helps maintenance teams identify abnormal behavior and usage patterns. Service activities can be planned based on actual machine condition and usage history rather than fixed intervals, reducing unexpected breakdowns and improving equipment availability.

Industrial Communication and Data Integration

The monitoring controller supports both mechanical and electronically controlled machines. For machines equipped with electronic control units, CAN-based data acquisition using the J1939 protocol enables detailed monitoring of engine and system parameters. Data can also be acquired through analog and digital inputs, RS485 MODBUS, and Ethernet interfaces, allowing flexibility across different machine types.

Location Tracking and Geo-Fencing

For mobile and high-value equipment, integrated GPS enables location tracking through a map-based interface. Geo-fencing functions allow operating boundaries to be defined and movement history to be reviewed, supporting asset tracking and operational accountability.

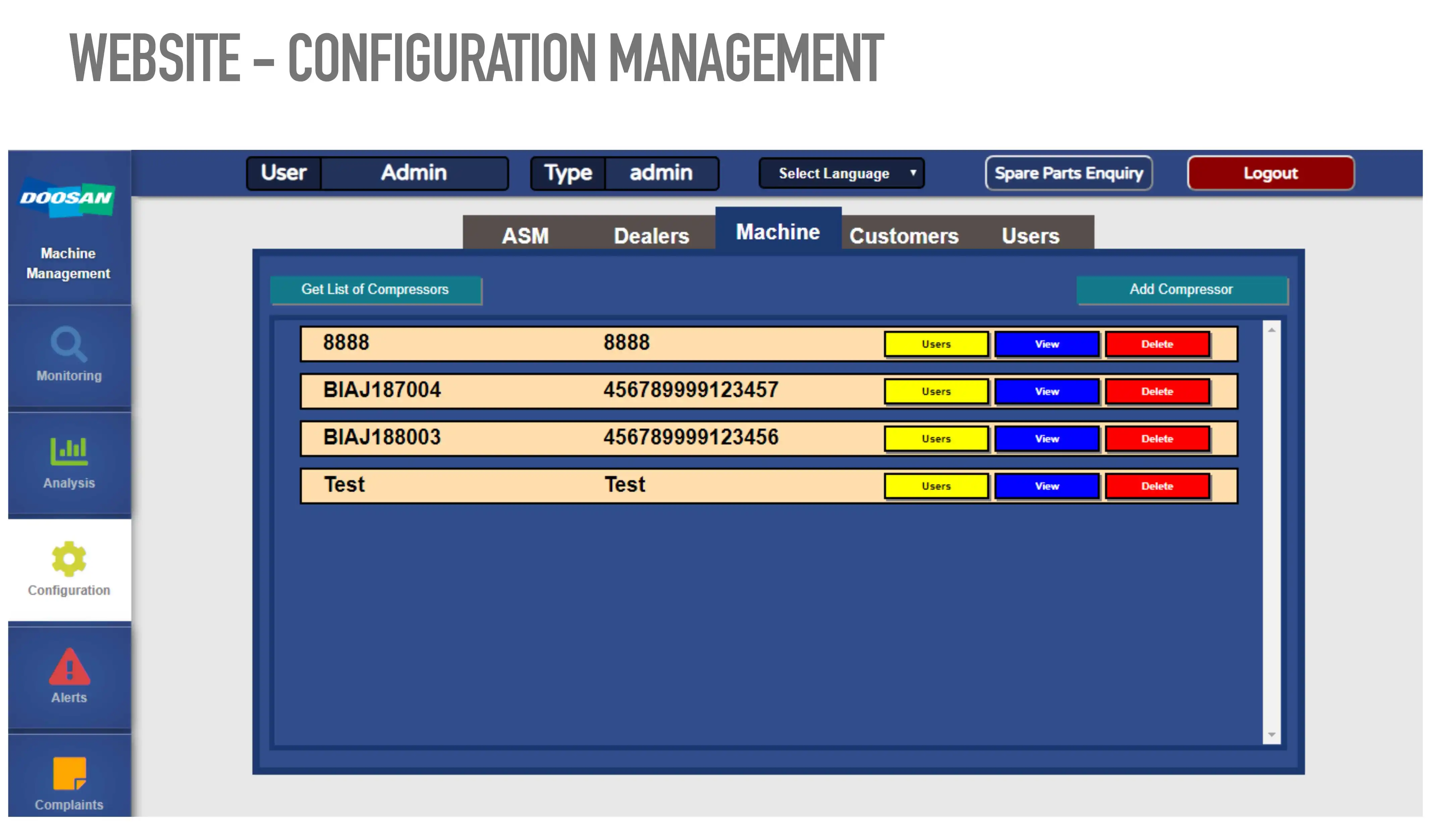

Cloud Dashboard and Access Control

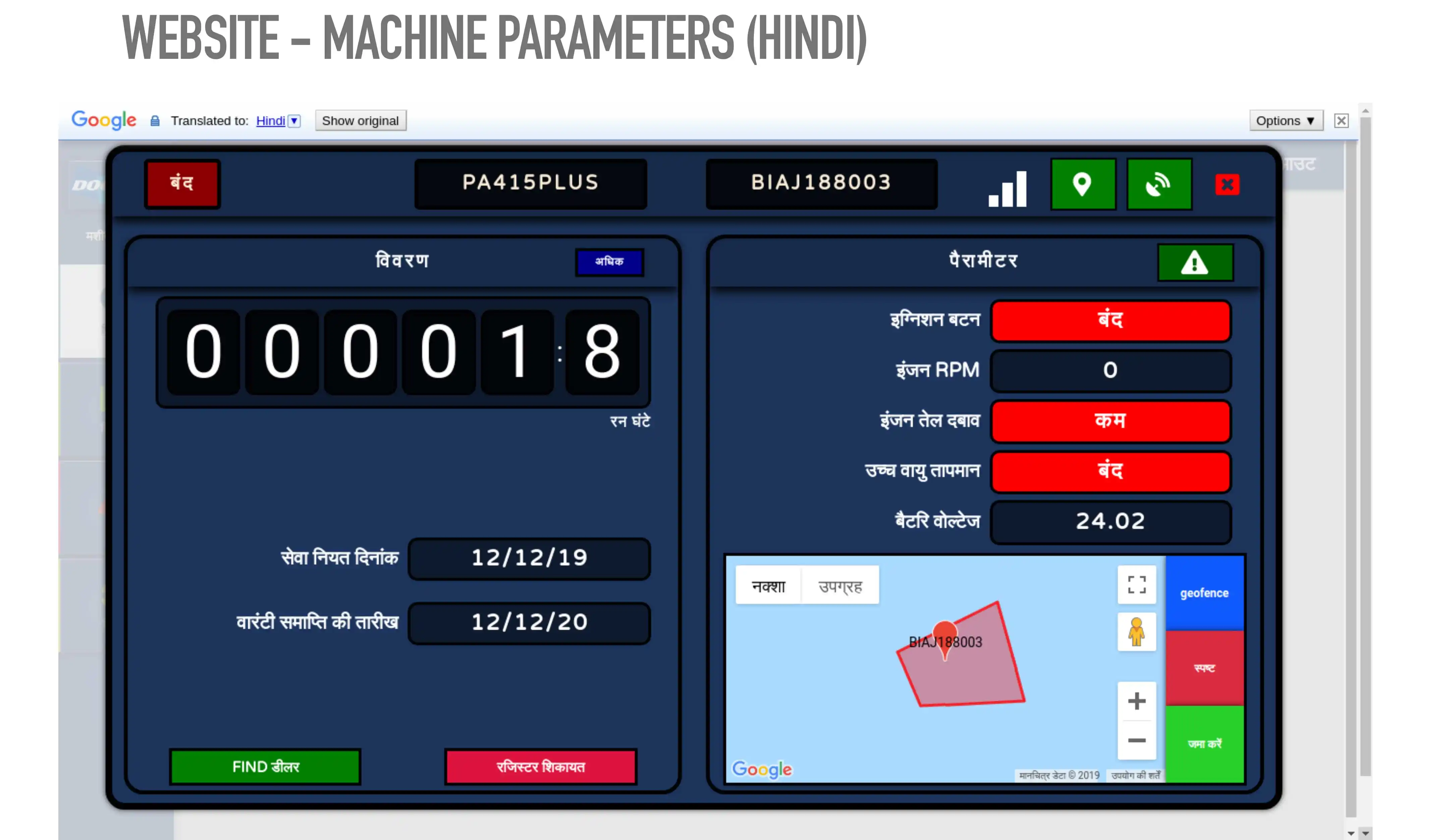

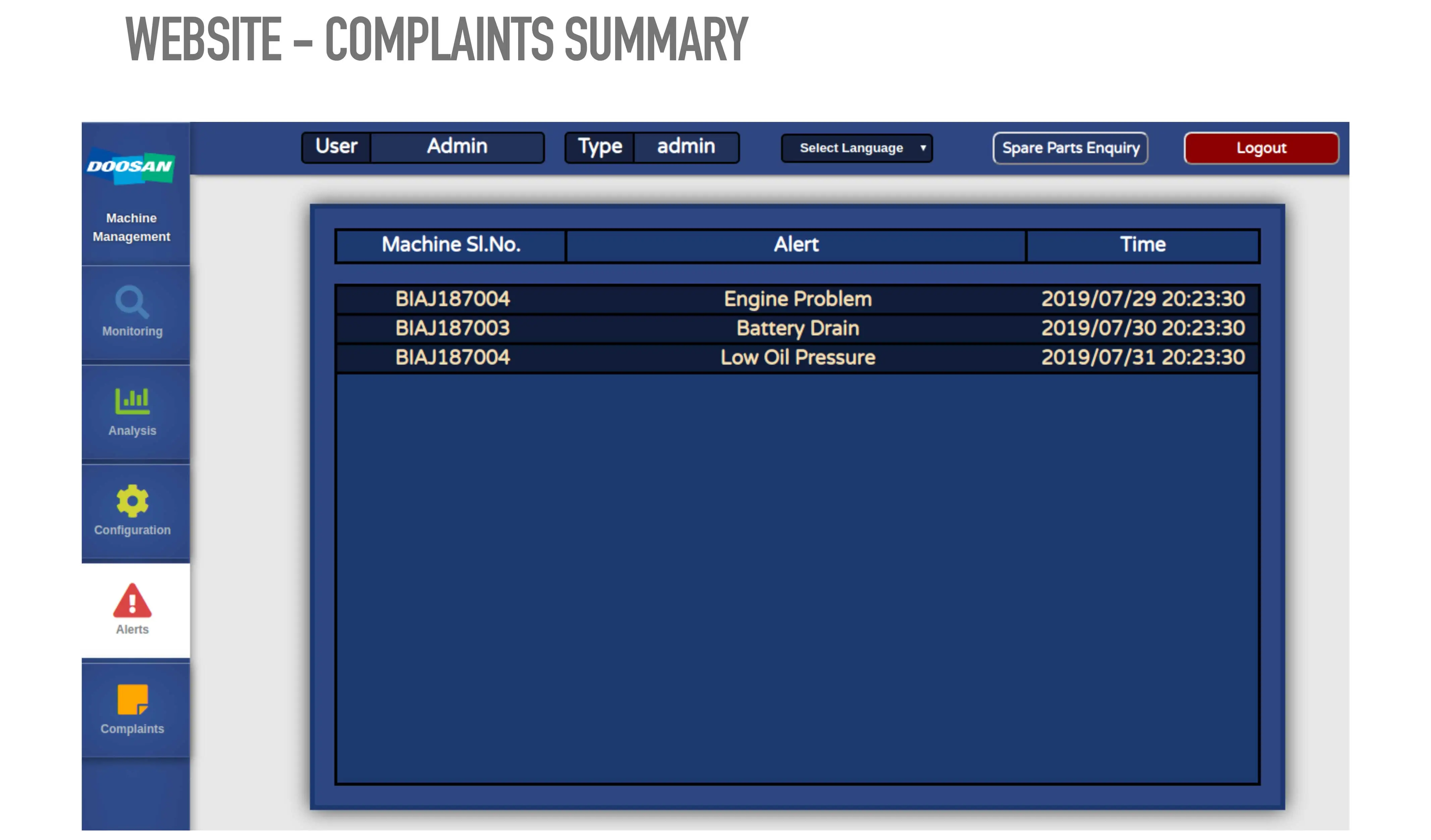

The cloud dashboard provides centralized access to live machine data, alerts, and historical records. Role-based access control allows different users such as machine owners, dealers, service personnel, and administrators to access relevant information based on their role.

Users can review machine status, analyze usage history, receive alerts, and track service schedules from desktop or mobile devices. Notifications are delivered through the web portal and supported communication channels such as SMS and email.

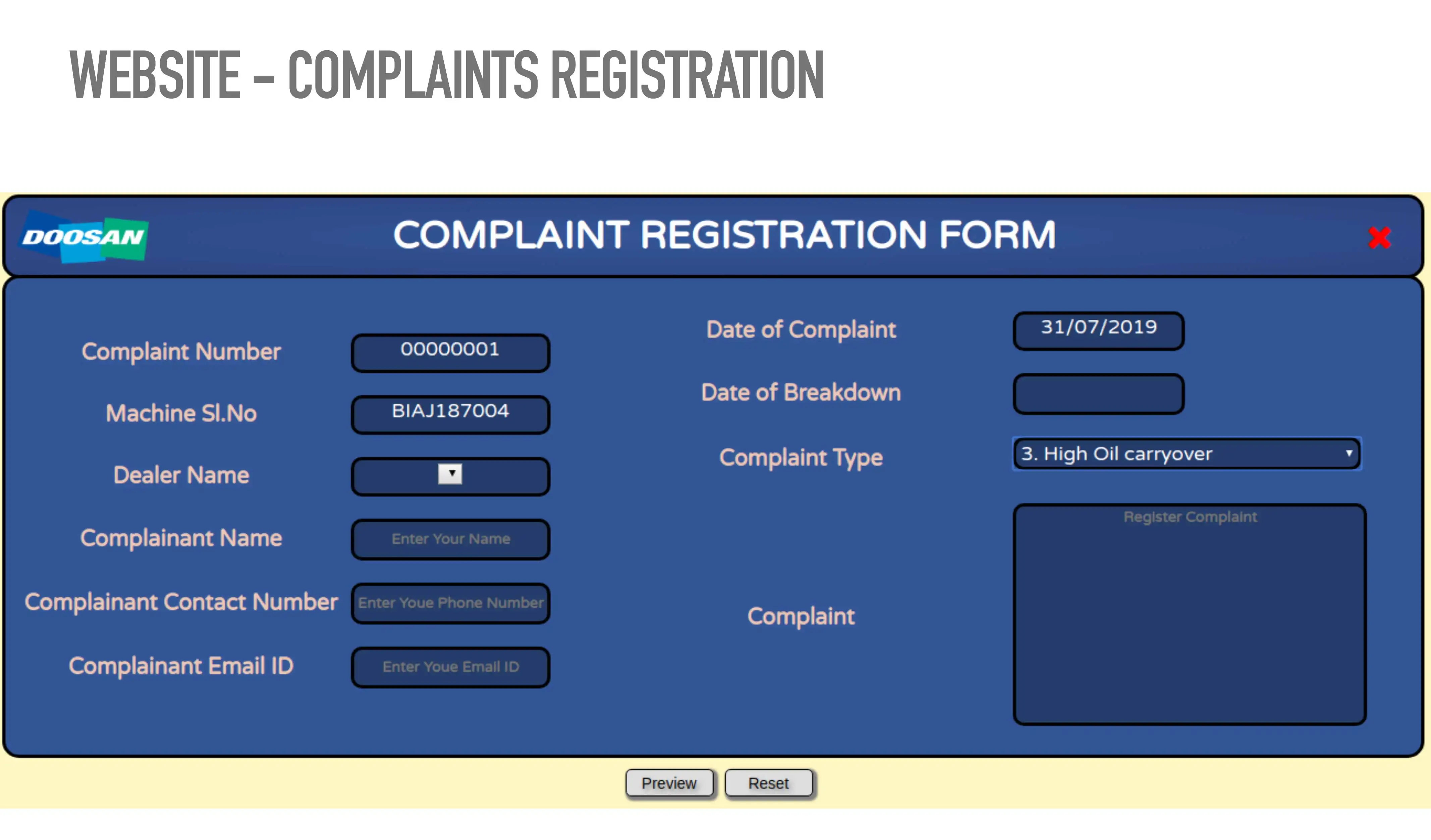

Service and Support Management

The platform supports structured service workflows by maintaining machine-level records, operating history, and event logs. This improves coordination between end users, dealers, service teams, and OEM support functions.

Historical data provides objective records for validating service actions, maintenance decisions, and warranty-related discussions.

Typical Applications

MicroLOGIX Machine Monitoring Solutions are used across industries that depend on high-value or mission-critical equipment. Common applications include construction machinery, mining and drilling equipment, compressors, generators, material handling equipment, and other industrial assets operating in fixed or mobile environments.

The system adapts to different machine types and operating conditions without enforcing rigid configurations that do not reflect real-world usage.

Technical Overview

The solution uses industrial-grade monitoring hardware with integrated GSM/GPRS/WiFi communication and GPS positioning. It supports data acquisition through machine sensors, CAN J1939 interfaces, and industrial I/O. Parameters related to speed, pressure, temperature, load, fuel usage, and operating hours are recorded with date and time stamps.

The cloud-based interface is designed to support continuous monitoring, historical data analysis, and multi-user access across distributed machine deployments.

Applications

Fork Lift Truck

Wheel Loader

Rigid Dump Truck

Reach Stacker

Deep Drilling Compressor

Dump Truck

Rotary Drilling Machine

Business Benefits

With MicroLOGIX Machine Monitoring Solutions, organizations gain clearer visibility into machine operations, improved maintenance planning, and reduced unplanned downtime. Decisions are supported by accurate operational data rather than manual logs or assumptions. Over time, this contributes to better asset utilization, longer equipment life, and more predictable operating costs.