The electronics world moves fast today. Companies must bring products to market quickly. They also need to ensure quality and reliability. Rapid prototyping in electronics is now the key to staying competitive.

At MicroLOGIX, we know that every day counts. Our electronic prototyping services help bridge the gap between great ideas and market-ready products. We help companies test designs, reduce risks, and speed up their time-to-market.

Table of Content

Why Rapid Prototyping is Crucial in Electronics Development

Reducing Financial Risk through Early Testing

Product failures cost companies millions of dollars. Recalls and repairs damage both budgets and reputations. PCB prototyping helps engineers find design problems before mass production starts. This early detection stops costly mistakes later.

Think about this example. A medical device company makes 10,000 units. Then they discover a heating problem. The cost of recalls, redesign, and reputation damage is huge. It costs much more than proper prototype testing would have cost.

Getting to Market Faster

The old product development cycle took months or years. Today’s rapid prototyping cuts these timelines drastically. Companies using smart electronic product development strategies can:

- Test many design ideas quickly

- Check if products work early in the process

- Make smart choices based on real data

- Launch products before competitors do

Testing Designs and Making Improvements

Prototype testing shows how products work in real conditions. Engineers can fix designs based on actual performance data. They don’t have to rely only on calculations. This iterative testing approach creates better final products.

Prototyping Services at MicroLOGIX

Quick-turn PCB Fabrication

Our quick-turn PCB fabrication service delivers circuit boards fast. We know that waiting weeks for PCBs slows down entire projects. Our smooth process handles all board types.

We use advanced manufacturing methods to ensure consistent quality. We handle everything from simple single-layer designs to complex multilayer circuits. Every board meets your exact requirements.

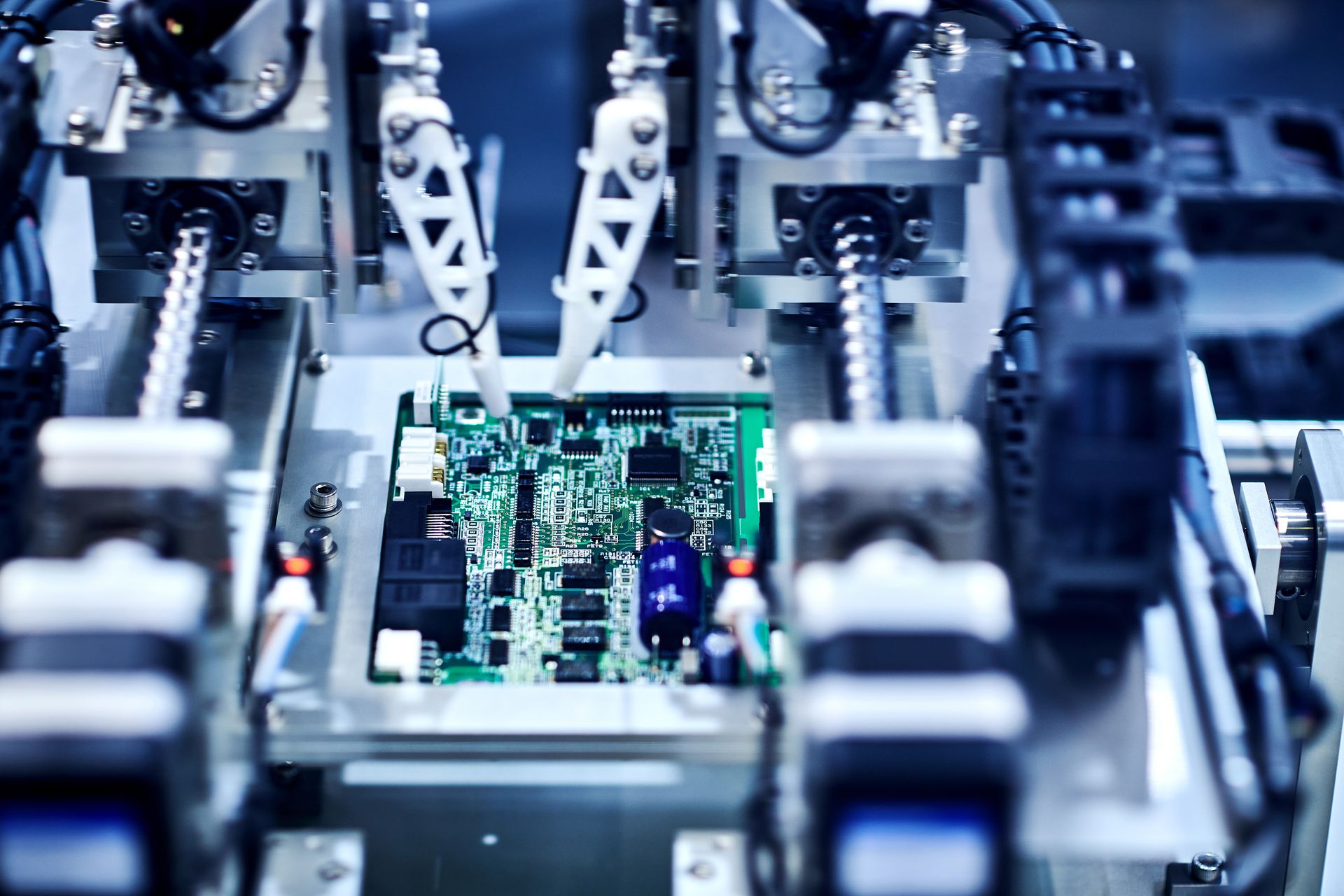

SMT Assembly & Advanced Packaging

SMT assembly prototyping needs special skills and equipment. Our modern facilities handle the most challenging components:

- Ball Grid Array (BGA) packages

- Chip Scale Packages (CSP)

- Very small components down to 0201 packages

- Micro Ball Grid Array (μBGA) assemblies

These advanced parts need precise placement and expert handling. Our experienced team makes sure every component meets your specifications.

3D Printing & Enclosure Making

3D printing electronics cases speeds up mechanical design. Custom housings protect circuits while being user-friendly. Our fabrication services include different materials and finishes.

We choose materials based on what you need. Industrial applications might need tough ABS plastics. Consumer products benefit from nice-looking finishes.

Testing Functions & FMEA Analysis

Functional prototyping goes beyond basic assembly. We check that prototypes work as planned through complete testing. Our FMEA analysis finds potential problems before they affect production.

We test heat levels to ensure components work safely. We also test mechanical strength under expected stress conditions.

Complete Assembly & Box Build

Full system integration brings all parts together. Our box build services turn individual PCBs into finished products. This includes wire preparation and final assembly processes.

Advanced Quality and Inspection Methods

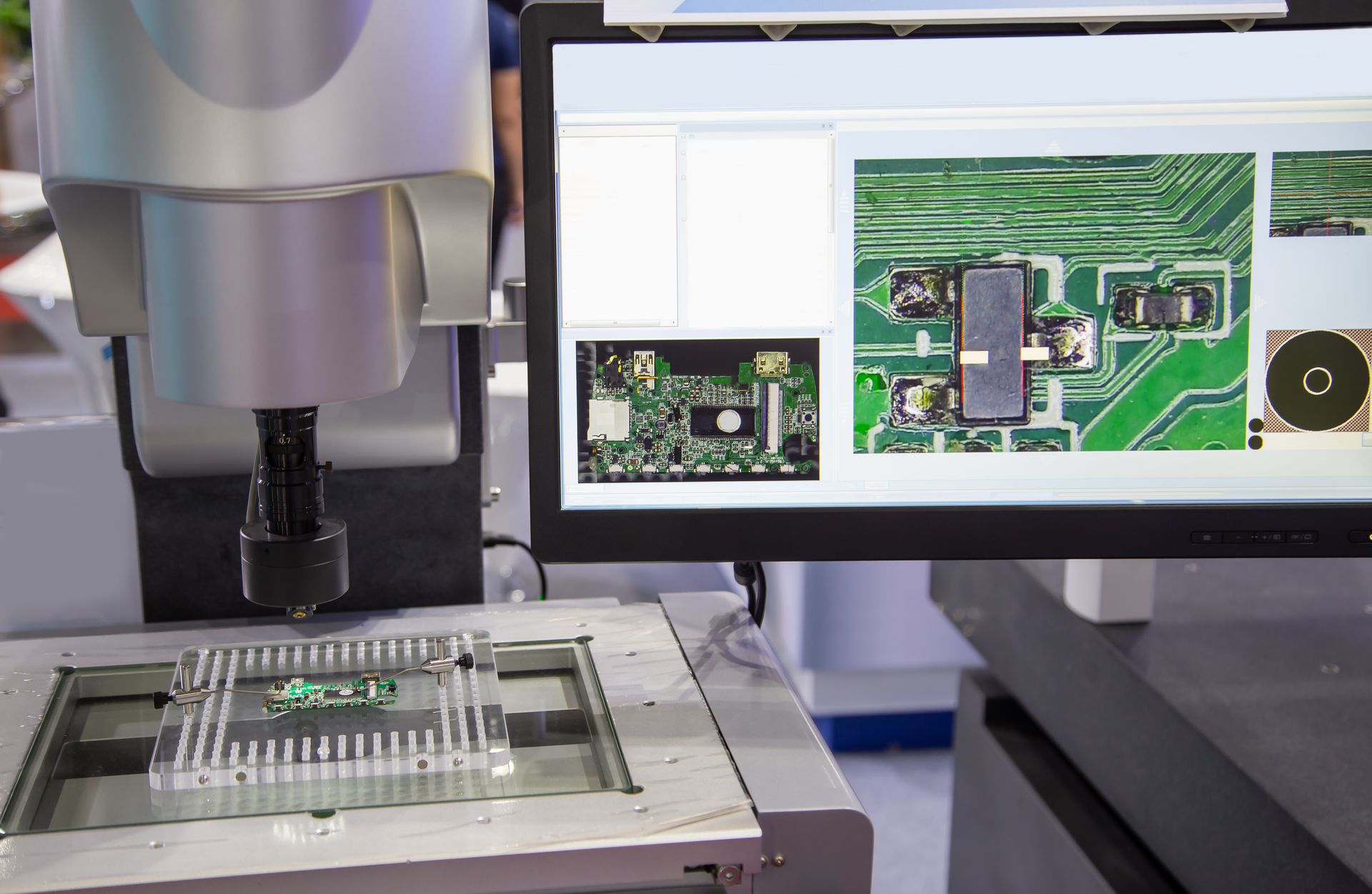

Precision Inspection Tools

Quality control starts with the right inspection methods. Our Automated Optical Inspection (AOI) systems catch defects that human eyes might miss. X-ray inspection finds hidden solder problems, especially important for BGA components.

Specialized Repair Services

When problems happen, our BGA rework services save time and materials. Instead of throwing away entire boards, we can remove and replace problem components with surgical precision. We have a dedicated team with X-ray inspection for BGA rework capabilities, fast import of components, especially for rapid prototyping customers.

Meeting Standards

ESD-compliant packing protects sensitive components during shipping. Our UL/CE marking support ensures prototypes meet international standards from the start.

Industries That Benefit from Rapid Prototyping

Defense & Aerospace Uses

Defense electronics prototyping demands the highest reliability standards. Mission-critical systems cannot fail under extreme conditions. Our strict testing checks performance across temperature ranges, vibration levels, and electromagnetic environments.

Aerospace applications need components that work perfectly at high altitudes. They must also work in radiation-rich environments. Our prototyping process finds potential problems before expensive qualification testing begins.

Automotive & Industrial Solutions

Modern cars have hundreds of electronic systems. From engine management to entertainment systems, every circuit must work reliably. Circuit design for automotive applications faces unique challenges. These include temperature extremes and electrical noise.

Industrial automation systems control manufacturing processes worth millions of dollars. Prototype testing ensures these critical systems work reliably in harsh factory environments.

Healthcare & Energy Sectors

Healthcare electronics prototyping involves life-critical applications where failure is not an option. Medical devices must meet strict rules while keeping users safe. Our testing checks both function and safety margins.

Energy management systems control power distribution across smart grids. These systems need extensive testing to ensure stable operation under changing load conditions.

How MicroLOGIX Ensures Faster, Reliable Prototyping

MicroLOGIX – Leading Electronic Manufacturing Company, Bangalore

As a trusted electronic manufacturing company in Bangalore, MicroLOGIX has been serving clients across India and globally for over a decade. Our state-of-the-art facility combines advanced technology with skilled expertise to deliver superior prototyping solutions.

Trusted Component Supply

Reliable component sourcing in prototyping prevents project delays. We work with trusted suppliers like DigiKey, Mouser, and Element14. This ensures real components arrive on schedule.

Our procurement team checks component specifications and availability before projects start. This proactive approach prevents costly delays during assembly phases.

Complete EMS Solutions

Electronics manufacturing services extend beyond simple assembly. As a comprehensive electronic manufacturing company, we provide complete solutions from initial concept through final production. This integrated approach ensures consistency across all project phases.

We follow global standards to ensure prototypes meet international requirements. Whether you need European CE marking or North American UL standards, we understand regulatory landscapes.

Our electronic manufacturing services include:

- Contract manufacturing for various industries

- PCB assembly services with advanced capabilities

- Electronic component assembly using the latest technology

- Quality assurance programs meeting international standards

- Supply chain management ensures timely delivery

- Product lifecycle support from design to obsolescence

Solving Manufacturing Problems

Common manufacturing challenges include component shortages, supply chain disruptions, and quality variations. Our experienced team anticipates these issues and develops backup strategies.

Design validation happens throughout the prototyping process. Instead of waiting until final testing, we validate designs at each milestone. This approach catches issues early when fixes are less expensive.

As an established electronics manufacturing company, we leverage our extensive industry experience to provide custom manufacturing solutions tailored to each client’s unique requirements.

Why Choose MicroLOGIX for Electronics Manufacturing

Comprehensive Manufacturing Capabilities

Our electronic manufacturing services encompass the entire product development spectrum. From initial prototype development to full-scale production manufacturing, we serve as your complete technology partner.

Local Expertise with Global Standards

Being an electronic manufacturing company in Bangalore, we understand local market dynamics while maintaining international quality standards. Our manufacturing facility is equipped with:

- Advanced automated assembly equipment

- Comprehensive testing and inspection capabilities

- Clean room environments for sensitive applications

- Certified quality systems meeting ISO standards

Industry-Leading Manufacturing Solutions

Our electronics manufacturing company specializes in providing turnkey manufacturing services across multiple sectors. We combine lean manufacturing principles with advanced manufacturing technology to deliver exceptional results.

Our manufacturing expertise includes:

- High-volume manufacturing for consumer electronics

- Low-volume manufacturing for specialized applications

- Mixed-technology assembly combining different component types

- Box build assembly for complete system integration

Conclusion

Rapid prototyping in electronics transforms innovative concepts into successful products. The difference between market leaders and followers often comes down to development speed and prototype quality.

MicroLOGIX combines advanced manufacturing capabilities with deep industry expertise. Our comprehensive prototyping services support companies across diverse sectors. We help everyone from defense contractors to healthcare innovators.

As a leading electronic manufacturing company, we understand the unique challenges facing today’s electronics industry. Our electronic manufacturing services are designed to help companies navigate complex development cycles while maintaining the highest quality standards.

The electronics landscape keeps changing rapidly. Companies that invest in quality prototyping services position themselves for long-term success. Partner with MicroLOGIX to speed up your electronic product development. Bring innovative solutions to market faster.

Ready to transform your ideas into reality? Contact MicroLOGIX today to discuss your prototyping needs. Discover how our expertise as a trusted electronics manufacturing company can accelerate your product development timeline.