In electronics manufacturing, reliability is rarely defined by the PCB alone. While PCB design and assembly receive significant attention, many functional failures originate after the board is integrated into a system. Interconnections, particularly wire and cable harnesses, play a decisive role in how reliably power and signals move across assemblies.

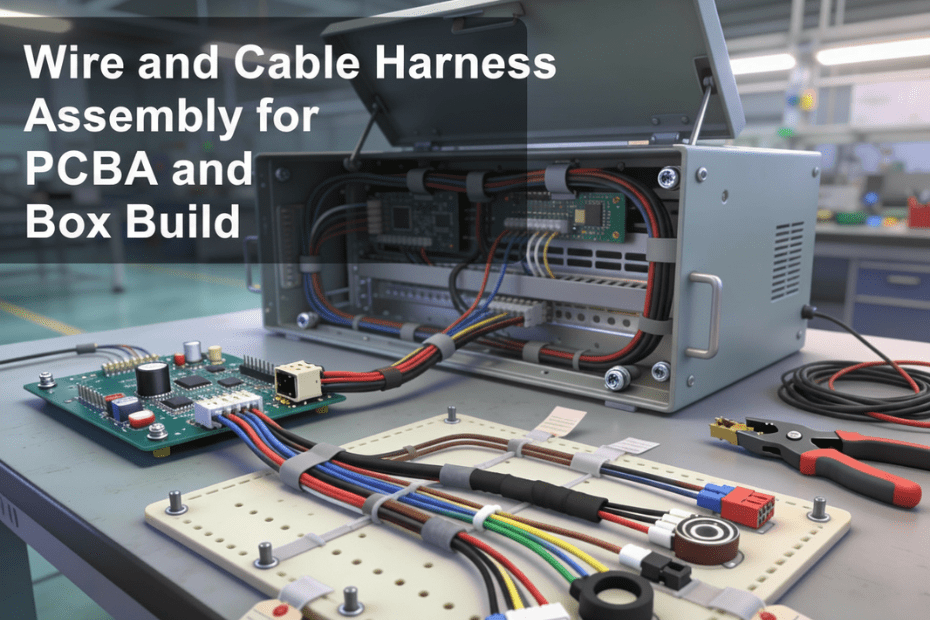

This is where wire and cable harness assembly services become a critical part of PCBA and box build manufacturing. Harnesses are not auxiliary components. They are engineered subassemblies that directly influence electrical stability, mechanical durability, assembly efficiency, and long-term product performance.

As electronic systems grow more compact and interconnected, the role of structured harness assembly continues to expand across industrial, medical, automotive, and IoT applications.

Table of Contents

Understanding Wire and Cable Harness Assembly in Electronics Manufacturing

A wire or cable harness is an organized system of conductors, connectors, terminals, and protective elements designed to transmit power and signals in a controlled and repeatable manner. In professional manufacturing environments, harness assembly is governed by defined engineering documentation, process controls, and inspection criteria.

In wire harness manufacturing, design decisions are based on both electrical and mechanical requirements. Wire gauge selection is influenced by current load and voltage drop. Insulation materials are chosen based on temperature range and environmental exposure. Connector systems are evaluated for mating cycles, retention strength, and compatibility with mating hardware.

When these factors are not controlled, harness-related issues often appear late in the production cycle or after deployment. This is why experienced EMS providers treat harnesses as system-level components rather than manual assemblies.

Types of Cables Used in Wire and Harness Assemblies

In professional harness assembly, cable selection is a design decision, not a procurement choice. Different cable constructions are used to manage electrical load, temperature, fire risk, and signal integrity within the system.

Common cable types used in PCBA and box build harnesses include:

Fire-resistant and flame-retardant cables

These cables are specified in systems where circuit integrity must be maintained under elevated temperature or fire exposure. They are commonly used in industrial equipment, transportation systems, and safety-critical electronics. Insulation materials are selected to limit flame propagation and reduce toxic emissions.

High temperature cables

Used where harnesses run close to power electronics, motors, or heat-generating PCBAs. These cables maintain dielectric stability and mechanical strength when standard PVC insulation would degrade.

Shielded signal cables

Low-voltage and high-speed signal lines require protection from electromagnetic interference generated by power circuits and switching devices. Shielded cables preserve signal quality and reduce the risk of data errors or control instability.

Power cables

Higher gauge conductors are used to carry current from power supplies to PCBAs, motors, and actuators while controlling voltage drop and thermal rise.

Flexible and high-flex cables

In applications involving vibration, movement, or repeated bending, conductor and insulation construction is optimized to prevent fatigue and cracking over the life of the product.

Role of Wire Harness Assembly in PCBA Manufacturing

Once a PCB leaves board-level assembly, its performance depends heavily on how it connects to other subsystems. In PCB assembly services, wire harnesses serve as the interface between the board and external components such as power supplies, sensors, motors, and communication modules.

Interconnection-related problems typically do not originate from solder joints or components. They are more often caused by inconsistent crimps, incorrect wire gauge selection, or uncontrolled strain at connector interfaces. These issues may pass basic inspection and only surface during system testing or field operation.

To mitigate such risks, professional wire harness assembly services are aligned with PCBA design and manufacturing data at an early stage. Harness specifications are reviewed alongside schematics to ensure compatibility and manufacturability.

Key integration considerations include:

- Verification of connector pin assignments against PCB schematics

- Wire gauge selection based on electrical loading requirements

- Defined strain relief to protect connectors and solder joints

- Controlled routing to reduce mechanical stress and EMI exposure

By addressing these factors during PCBA planning rather than after assembly, manufacturers reduce rework, improve first-pass yield, and achieve more stable functional test results.

Importance of Harness Assembly in Box Build Manufacturing

The role of wire and cable harnesses becomes even more pronounced during box build assembly, where multiple PCBAs and electromechanical components are integrated into a final enclosure. At this stage, harnesses function as the central interconnection architecture of the product.

Without enclosure-specific harness design, assembly teams often encounter excess cable length, unclear routing paths, or inconsistent installation methods. These conditions increase assembly time and elevate the risk of wiring errors.

In professional cable assembly manufacturing, harnesses are engineered with enclosure geometry and assembly sequence in mind. This allows for faster installation, consistent routing, and improved repeatability across production batches.

Well-designed box build harnesses typically incorporate:

- Defined breakout points aligned with component locations

- Clear labeling to support fast identification during assembly

- Secure fastening points to prevent vibration-related wear

- Routing paths that maintain airflow and service access

This structured approach improves both manufacturing efficiency and long-term serviceability of the final product.

Harness Applications in Automotive and Aerospace Systems

Automotive and aerospace electronics illustrate the system-level importance of harness design and assembly.

In automotive systems, wire harnesses distribute power and signals between engine control units, battery management systems, sensors, and vehicle networks. These harnesses must operate under continuous vibration, wide temperature ranges, and exposure to moisture and chemicals while maintaining electrical stability over long service life.

In aerospace systems, harnesses interconnect avionics, flight control electronics, and power distribution modules. Requirements typically include controlled impedance signal cables, EMI shielding, fire-resistant insulation, and strict documentation and traceability. Harnesses are built and tested to meet both electrical and mechanical reliability criteria before installation.

These environments demonstrate why harnesses are engineered subsystems rather than manual wiring tasks.

Wire Harness Manufacturing Process and Quality Controls

Reliable harness assembly begins with engineering validation. Electrical drawings, bills of materials, and mechanical constraints are reviewed to ensure alignment with functional and environmental requirements.

Production activities include controlled wire cutting, stripping, and crimping using calibrated tooling. Crimp integrity is a critical quality factor, as marginal crimps can result in intermittent electrical behavior over time.

Assembly is performed using predefined harness layouts to ensure consistency. Protective elements such as sleeving, conduit, or heat shrink are applied as required by the application environment.

Each harness undergoes inspection and testing in accordance with wire harness testing IPC standards, particularly IPC-WHMA-A-620. Typical quality controls include:

- Continuity verification

- Insulation resistance testing

- Visual inspection against IPC acceptance criteria

These controls ensure that harness assemblies meet reliability expectations before integration into higher-level assemblies.

Safety and Reliability of Wire Harnesses

In system-level electronics, wire harnesses represent one of the primary safety and reliability boundaries. Failures in interconnections can lead to loss of power, incorrect sensor readings, or unstable system behavior even when PCBAs are functioning correctly.

To control these risks, harness manufacturing applies multiple layers of process control:

- Crimp quality is managed through calibrated tooling and verification to prevent high-resistance joints and intermittent connections.

- Strain relief and mechanical retention are used to protect terminals and PCB interfaces from vibration and handling forces.

- Insulation and sleeving materials are selected based on temperature, flammability, and environmental exposure.

- Electrical testing verifies continuity, insulation integrity, and correct circuit routing before integration.

These controls ensure that harness assemblies perform predictably throughout the operating life of the system.

Why OEMs Work with Wire Harness Manufacturers in India

India has established itself as a reliable manufacturing base for electronics and interconnect assemblies. Leading wire harness manufacturers in India combine skilled labor, process discipline, and IPC-compliant quality systems.

When harness production is integrated with electronic manufacturing services in India, including PCBA and box build capabilities, OEMs benefit from a consolidated manufacturing workflow. This reduces coordination complexity and improves traceability across assemblies.

Many cable harness manufacturers in India also support prototyping and low-volume manufacturing, allowing OEMs to validate designs and make engineering updates before scaling production.

Turnkey Electronics Manufacturing and Harness Integration

Fragmented sourcing introduces unnecessary risk into electronics manufacturing. Managing separate vendors for PCB assembly, harness production, and final assembly often leads to misalignment and delays.

In turnkey electronics manufacturing, a single EMS provider manages sourcing, PCB assembly, wire harness assembly, and box build manufacturing under a unified quality system. Harness integration occurs in parallel with PCBA and mechanical assembly rather than as a downstream activity.

This approach enables faster engineering changes, improved configuration control, and more efficient final testing. For complex systems, turnkey manufacturing significantly improves time-to-market and production stability.

Supporting Low-Volume and High-Mix Manufacturing

Many industrial and specialized electronic products begin with pilot builds or customized configurations. In such cases, low-volume manufacturing capability is essential.

Experienced EMS providers support low-volume harness and box build production without rigid minimums. Design revisions, connector updates, and routing changes can be implemented efficiently, enabling controlled iteration without supply chain disruption.

This flexibility is particularly valuable during early-stage product development and validation.

Standards, Compliance, and Long-Term Reliability

Compliance with IPC standards is a baseline requirement for professional harness assembly. Beyond compliance, long-term reliability depends on disciplined process execution and documented quality controls.

For applications in industrial automation, medical devices, and critical infrastructure, consistent harness quality directly impacts product lifespan, warranty exposure, and customer trust.

Conclusion

Wire and cable harness assembly is not a secondary task within electronics manufacturing. It is a system-level function that directly affects PCBA performance, box build efficiency, and long-term product reliability.

By working with experienced wire harness assembly services and established cable harness manufacturers in India, OEMs gain access to controlled processes, scalable production, and integrated EMS capabilities.

When harness assembly is treated as a core manufacturing discipline rather than an afterthought, the result is a more reliable product and a more predictable manufacturing outcome.

FAQs

1. At what stage should wire harness assembly be planned in the manufacturing lifecycle?

Wire harness planning should begin at the system design stage, alongside enclosure and PCBA planning, not after PCB fabrication.

2. How does early harness planning reduce time-to-market?

It prevents late-stage routing changes, connector mismatches, and assembly rework during box build integration.

3. What typically causes delays in harness-related production?

Incomplete drawings, undefined wire lengths, late connector changes, and unclear routing paths are the most common causes.

4. How do EMS providers manage variation across multiple product configurations?

By using modular harness designs and controlled documentation to support high-mix and low-volume production efficiently.

5. What should OEMs review in a harness sample before production approval?

Crimp quality, labeling clarity, routing consistency, strain relief, and test documentation should all be reviewed.

6. How does harness design affect final product servicing?

Well-labeled and properly routed harnesses significantly reduce troubleshooting time during maintenance or replacement.

7. Can harness assembly influence thermal performance inside an enclosure?

Yes. Poor routing can block airflow, while optimized harness layout supports better heat dissipation.

8. How are harness-related failures typically traced during field issues?

Through continuity testing, connector inspection, and review of installation strain points rather than PCB-level diagnostics.

9. What changes when harness assembly is part of a turnkey EMS model?

Engineering updates, testing, and integration are handled faster because PCBA, harness, and box build teams work under one system.

10. When does it make sense to redesign an existing wire harness?

When scaling production, changing enclosures, improving serviceability, or addressing recurring field failures.